A Plastic Manifiesto.

Case

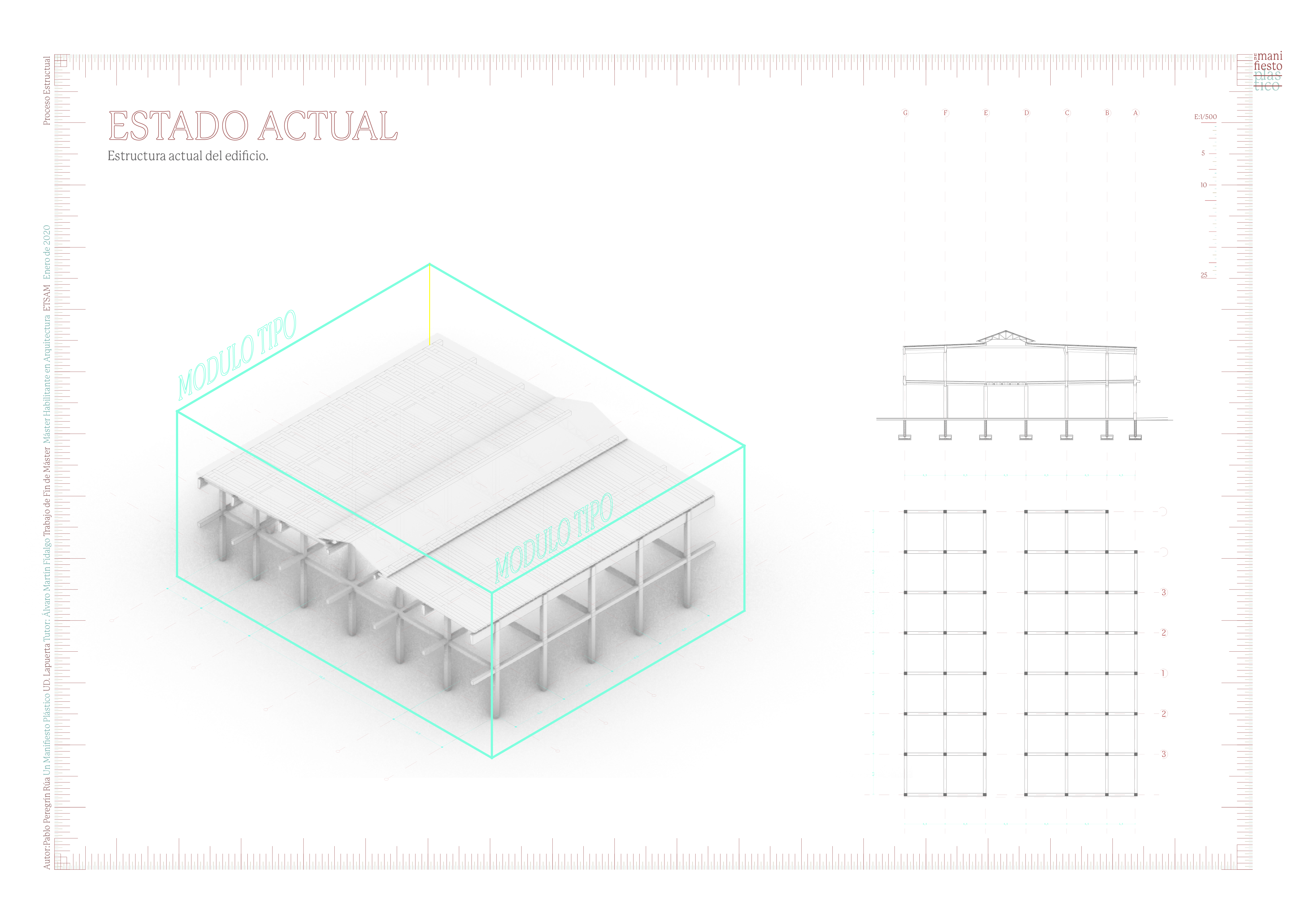

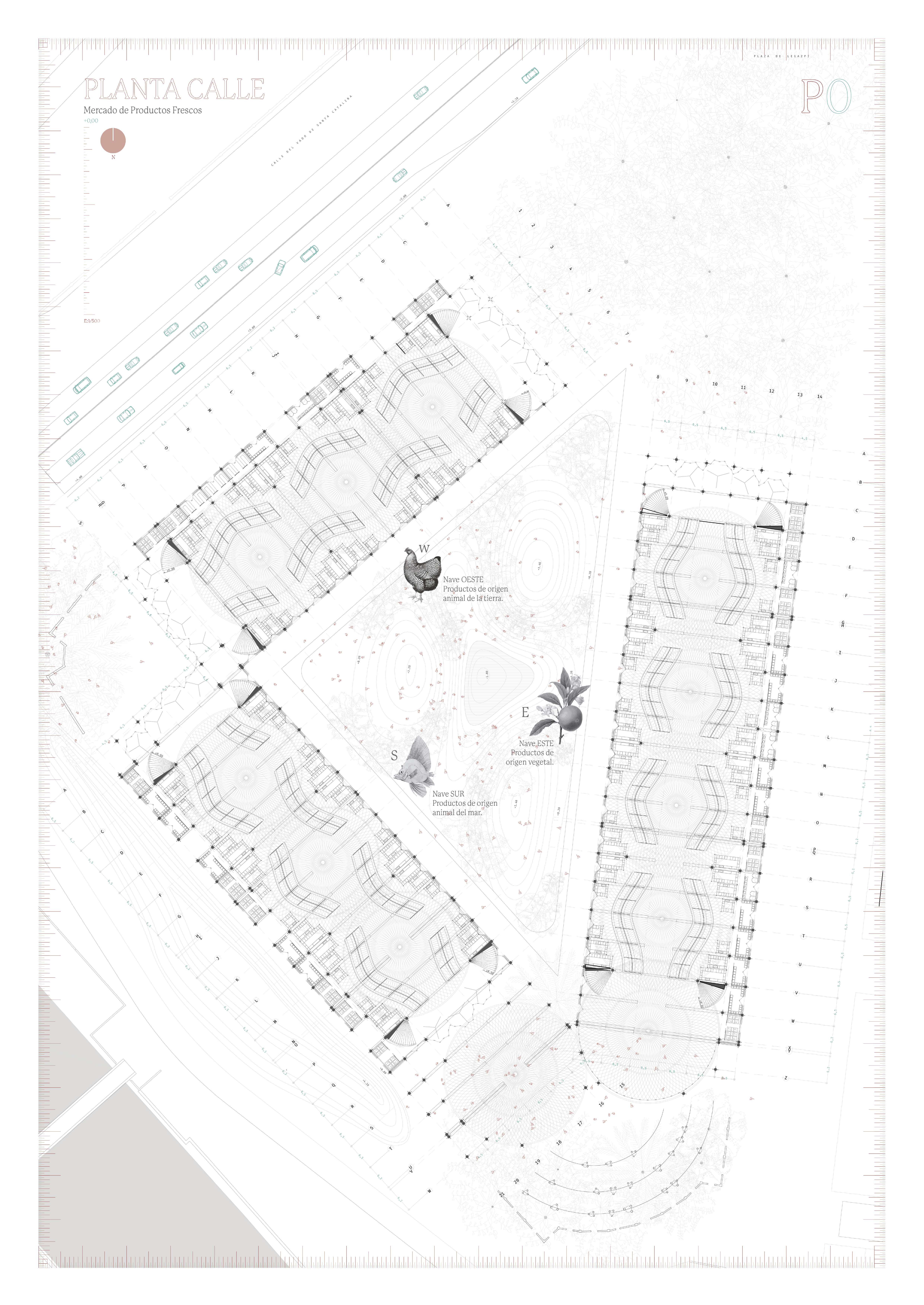

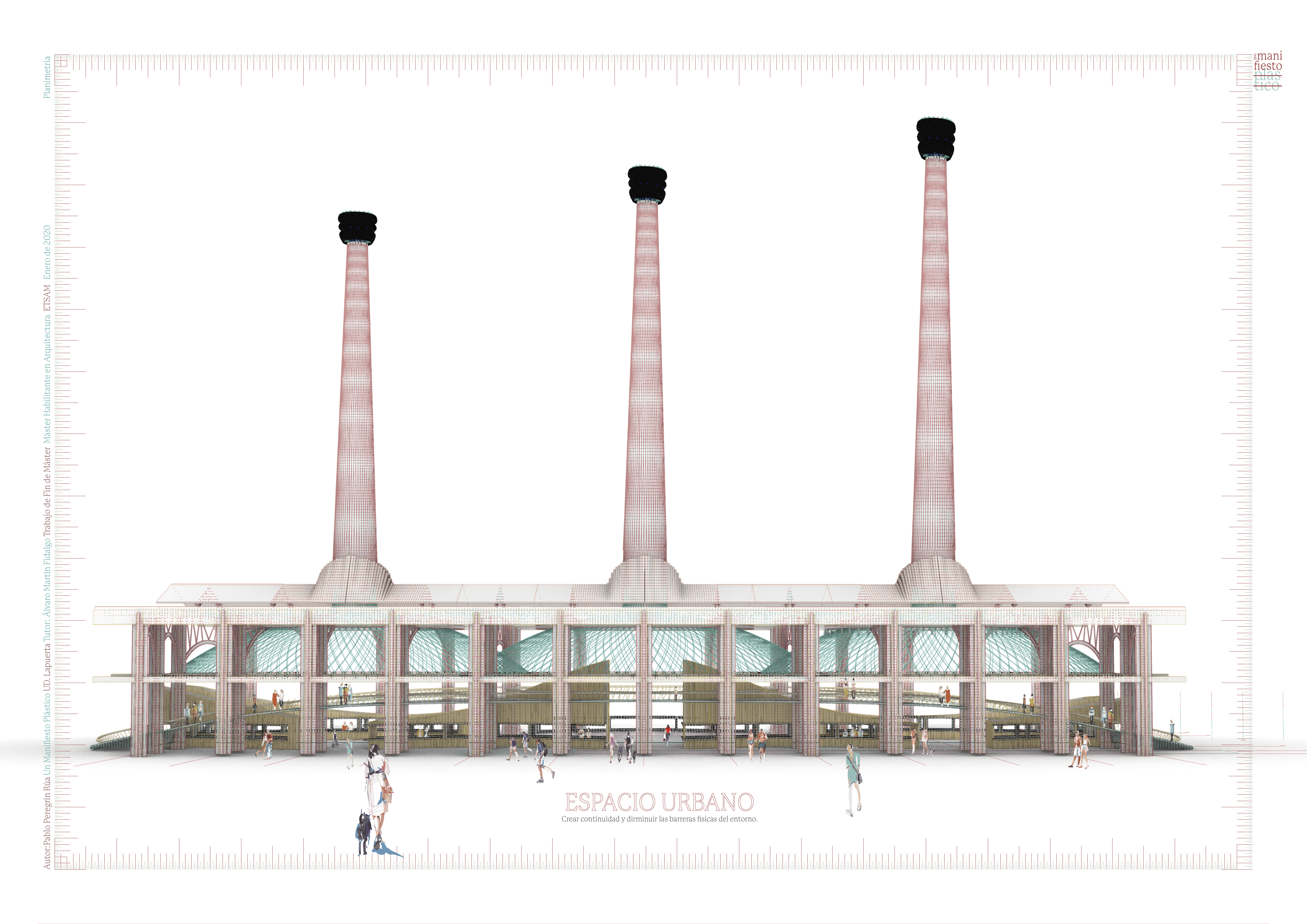

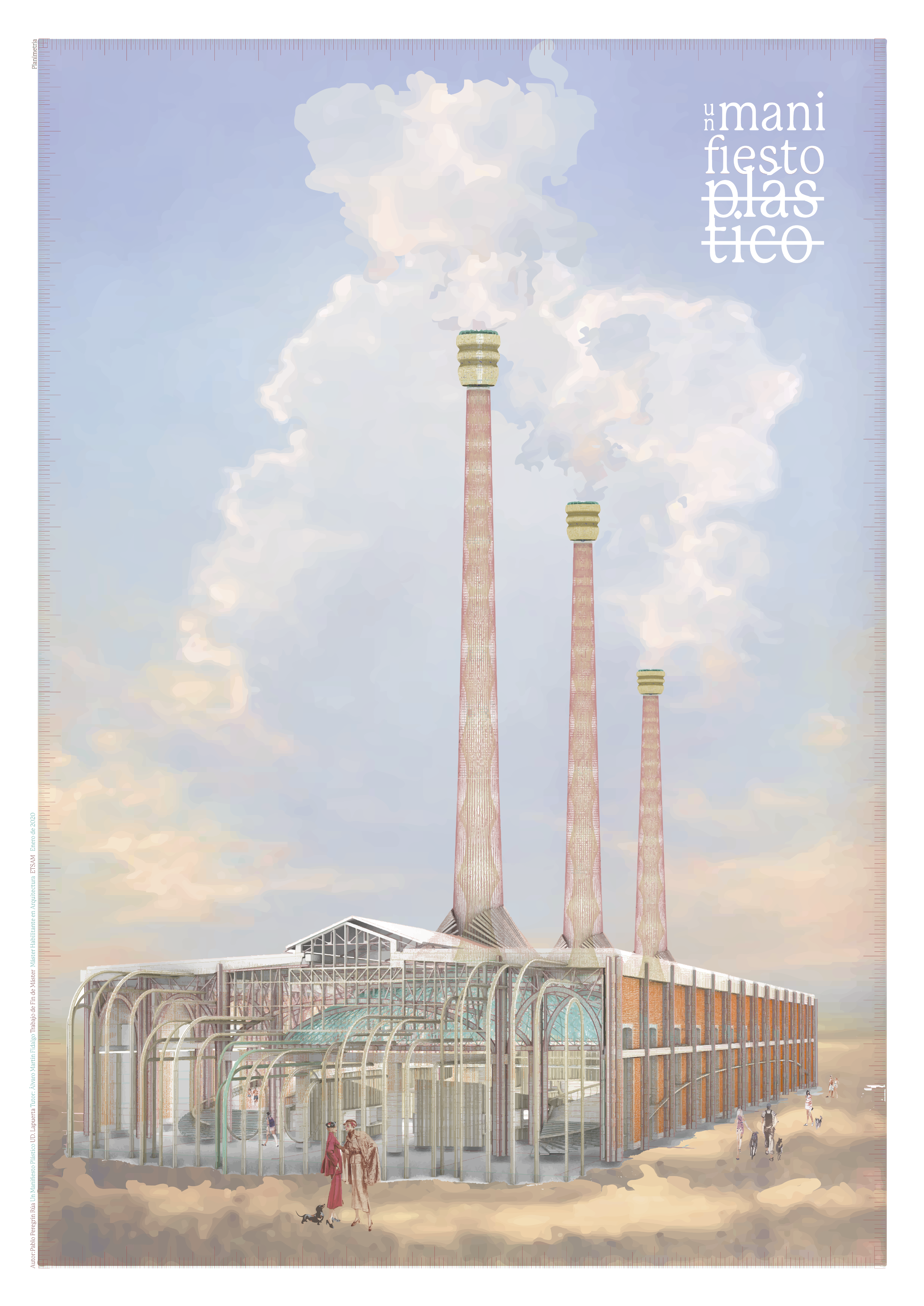

Rehabilitation of the old fruit and vegetable market of Legazpi in Madrid.

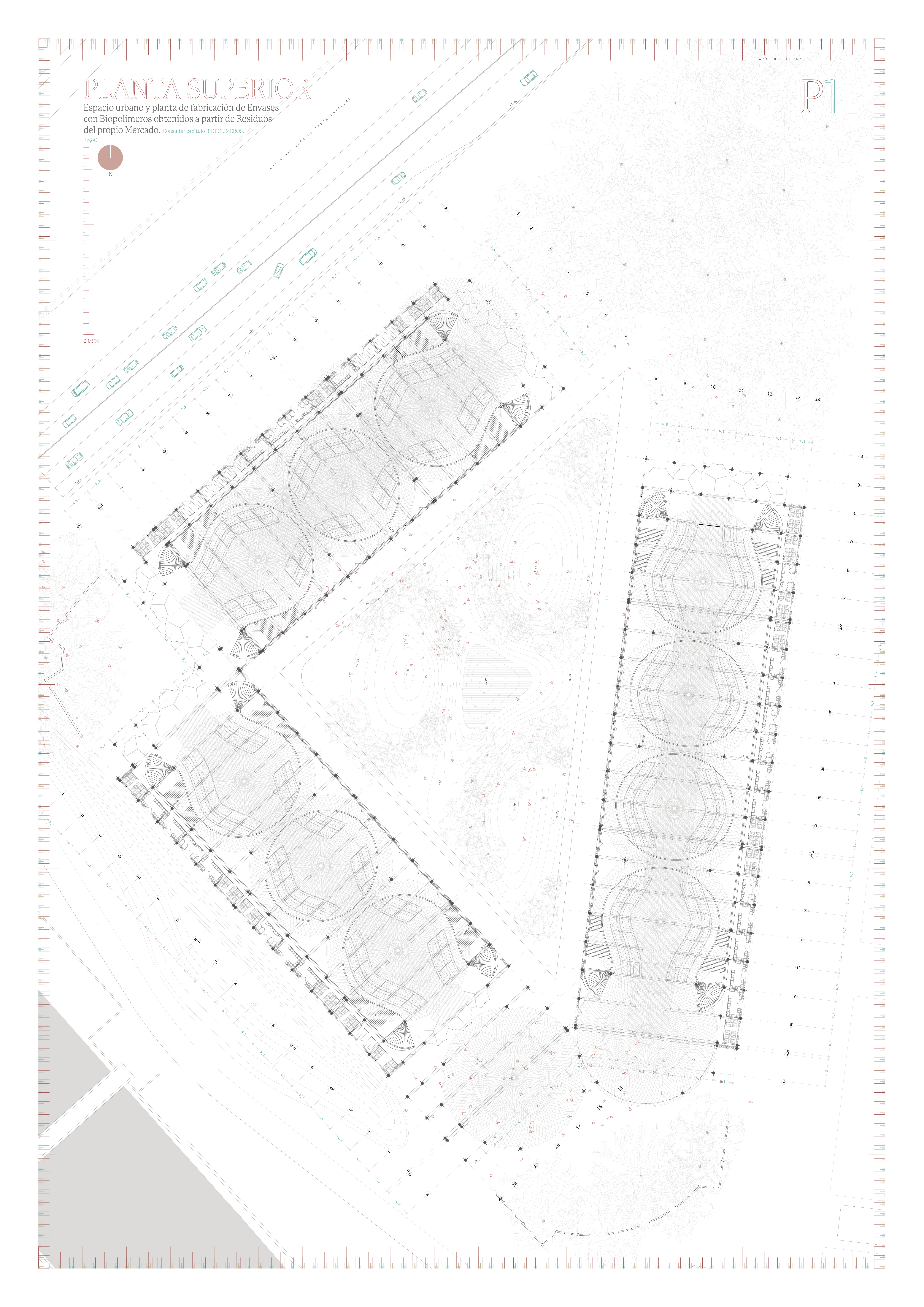

Exploration of the manufacture of packaging and construction elements with biopolymers from food waste offered in a new market for fresh produce.

Capabilities

Architecture.

Master Habilitante ETSAM.

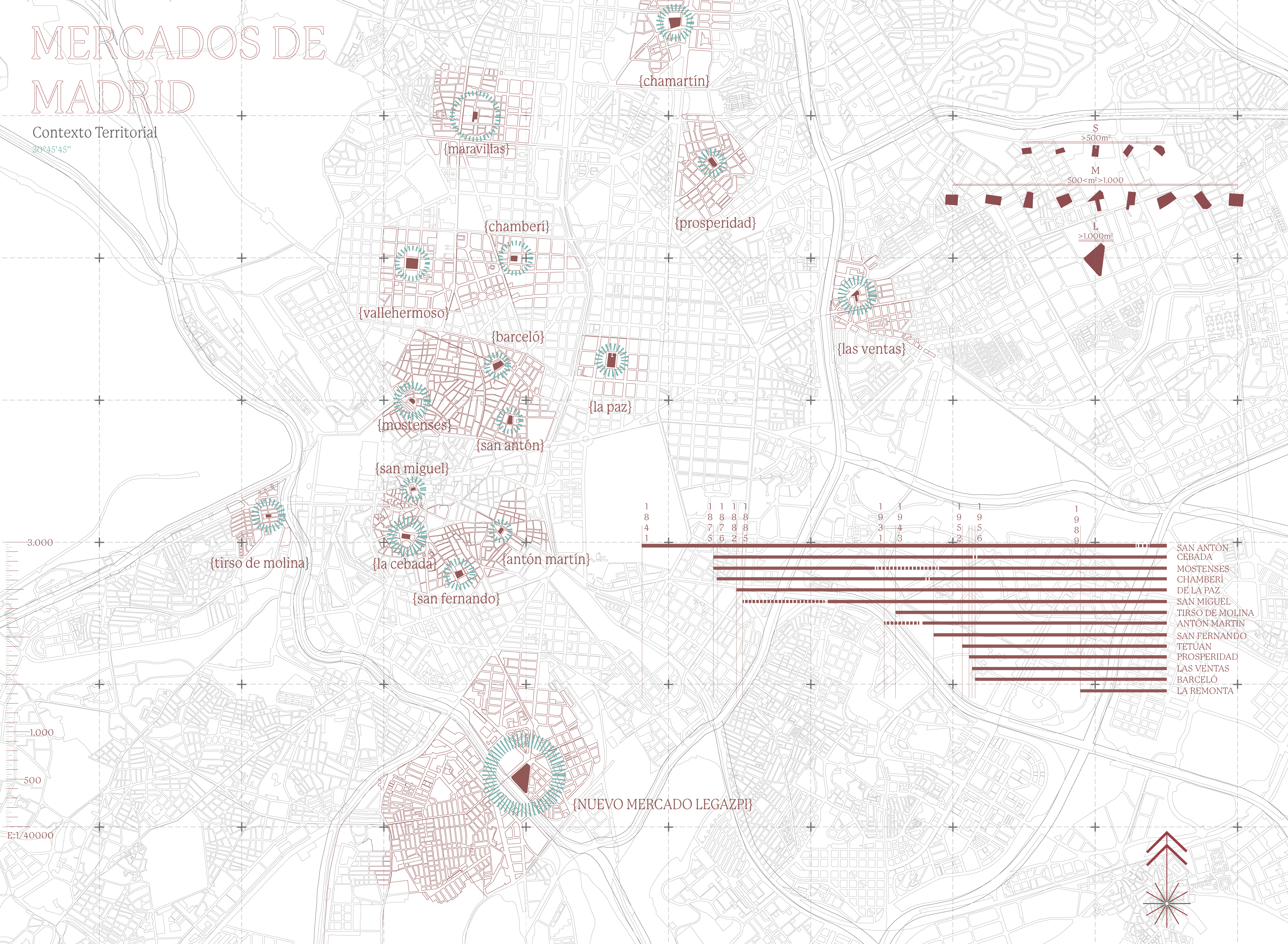

Context

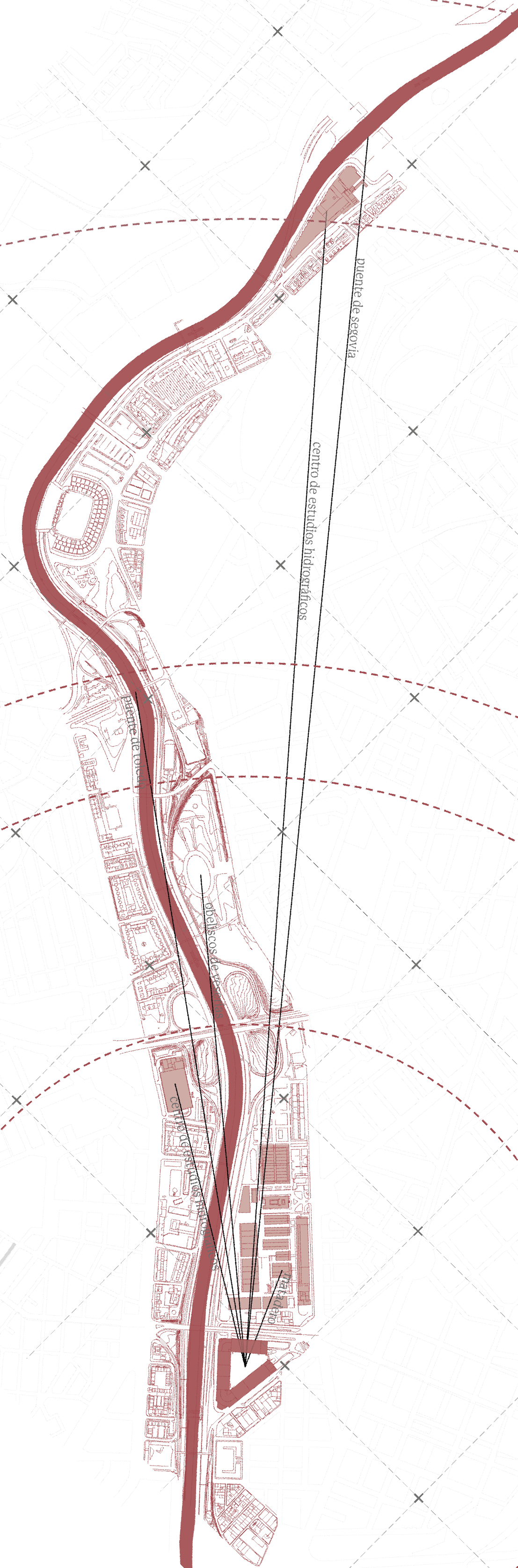

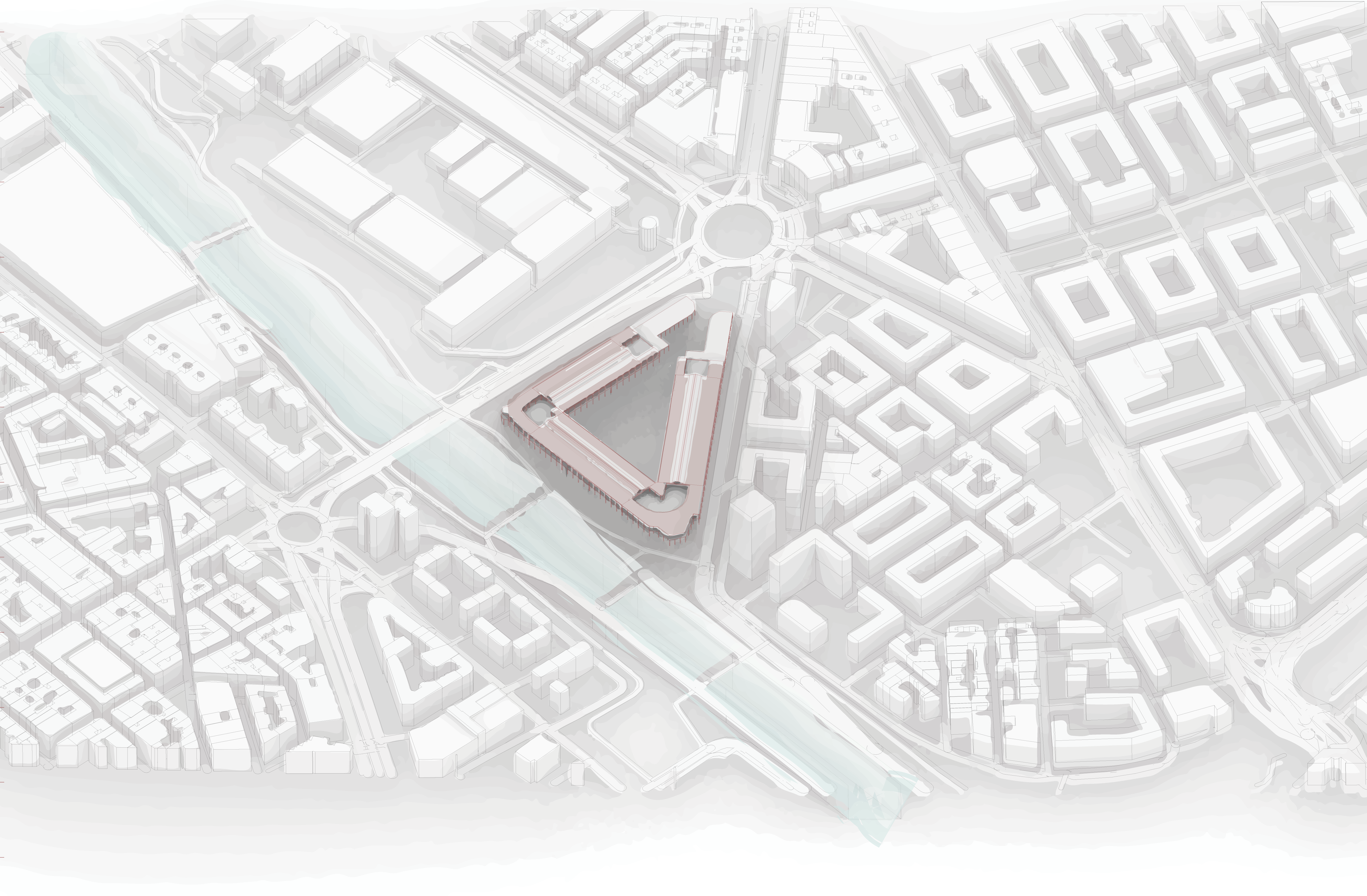

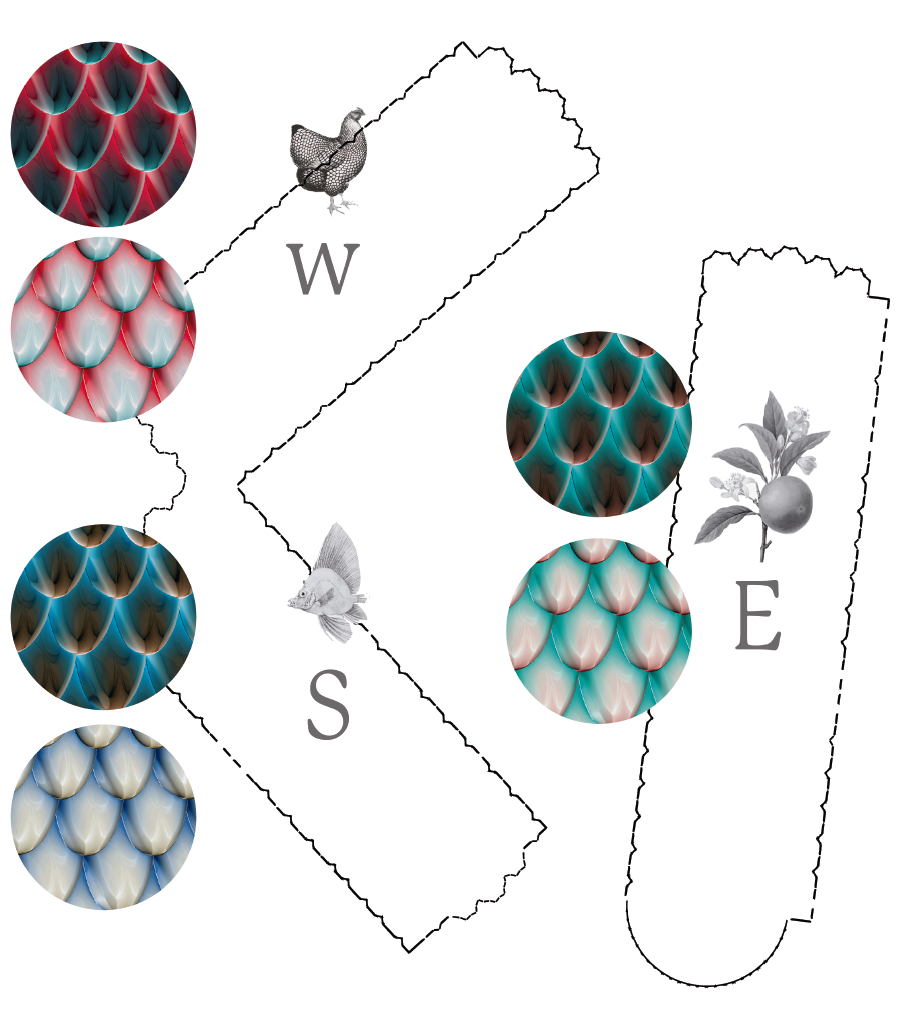

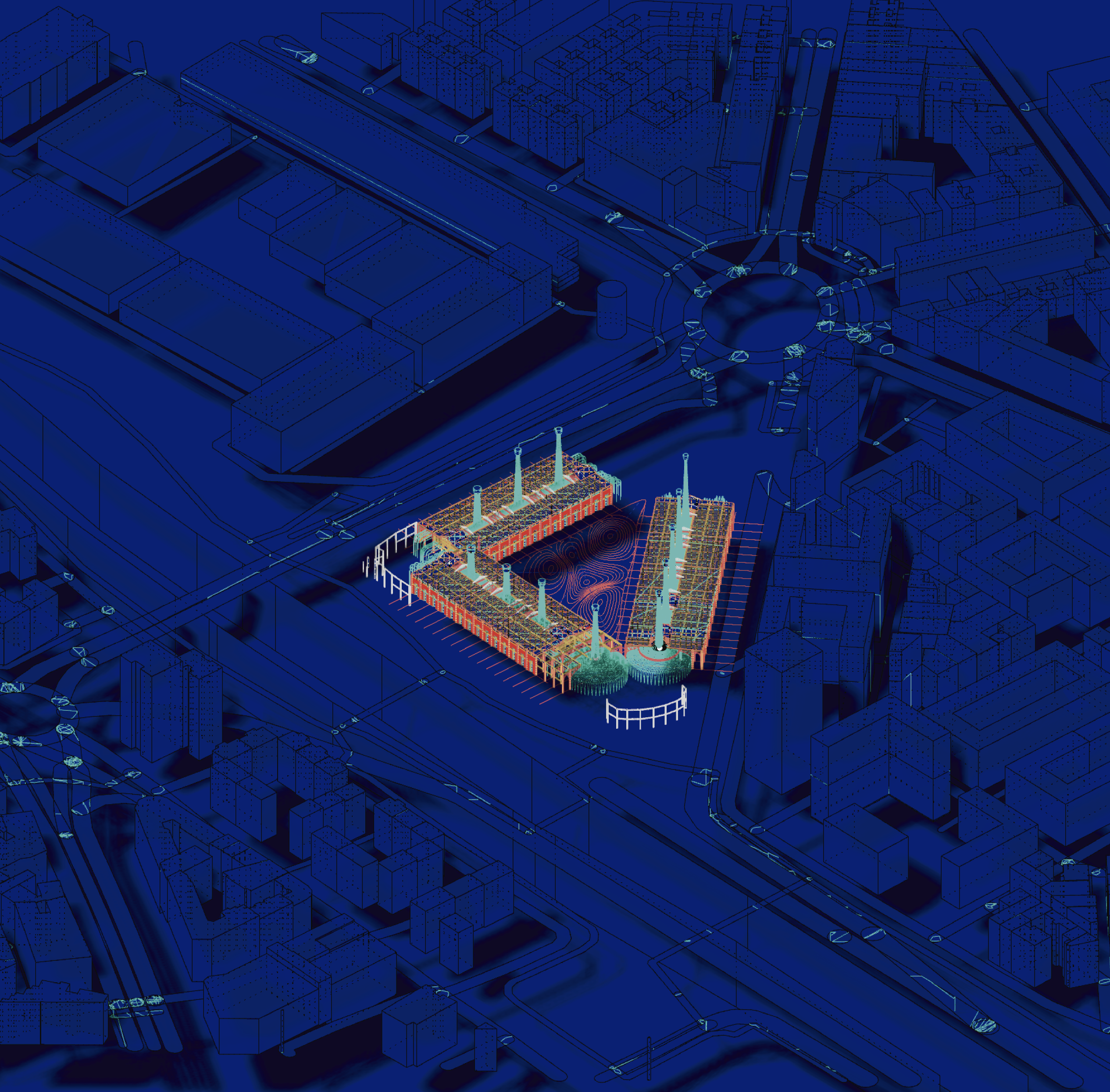

The traditional markets in the city leave the south of the city bare, so located at the end of the Castellana-Prado-Delicias axis, at the end of Madrid River, in the Plaza de Legazpi, on the banks of the Manzanares, we find the old fruit and vegetable market, a strategic enclave for the future south of the city. A traditionally industrial south, reconverted in the last two decades into a hybrid of residential and commercial areas.

Problem

The construction industry is the most polluting industry and the one that consumes the most natural resources for the planet.

- 36% of the earth's resources, materials, water and energy are consumed without return for the execution of a construction project.

- 33% of greenhouse gas emissions come from buildings.

- 60% of the world's waste comes from construction.

Most of the pollution produced by the food industry comes from its associated activities.

Obtaining raw materials and processing them into food only accounts for 35% of the environmental impact generated along the chain.

The felling of trees for the creation of non-recycled cardboard packaging, oil refining, the manufacture of plastic containers and packaging account for the majority of the environmental impact of the process.

If we add to this the fact that segregation in the chain increases distribution needs, we increase the impact even considering waste separation and traditional recycling, given that only 30% of waste is recycled in Spain.

Objectives

The project identifies as an experimental opportunity to bring together the food industry and the construction industry to propose solutions that benefit both sectors and thus reduce the environmental and pollution impact of fixed emissions.

It proposes a fresh food market that processes its own organic waste into packaging and eliminates emissions in the construction process of the building and its subsequent management.

The project proposes the rehabilitation of the old Fruit and Vegetable Market of Legazpi, to be connected to the network of neighbourhood markets in Madrid in the process of recovery, and for this purpose a threefold strategy is proposed:

1- The reactivation of public facilities that promote sustainable awareness.

2- The promotion of new experimental materials with waste from the market itself.

3- The search for and design of a self-sufficient bioclimatic system.

Program

It all starts from obtaining the raw materials, crops, forests, farms, ports, fish farms.

The processing of food into its derivatives.

Here the food is ready to be eaten, but only 30% of the total environmental impact of the chain has been generated.

This accounts for 65% of the contamination of the chain.

How can we reverse this situation?

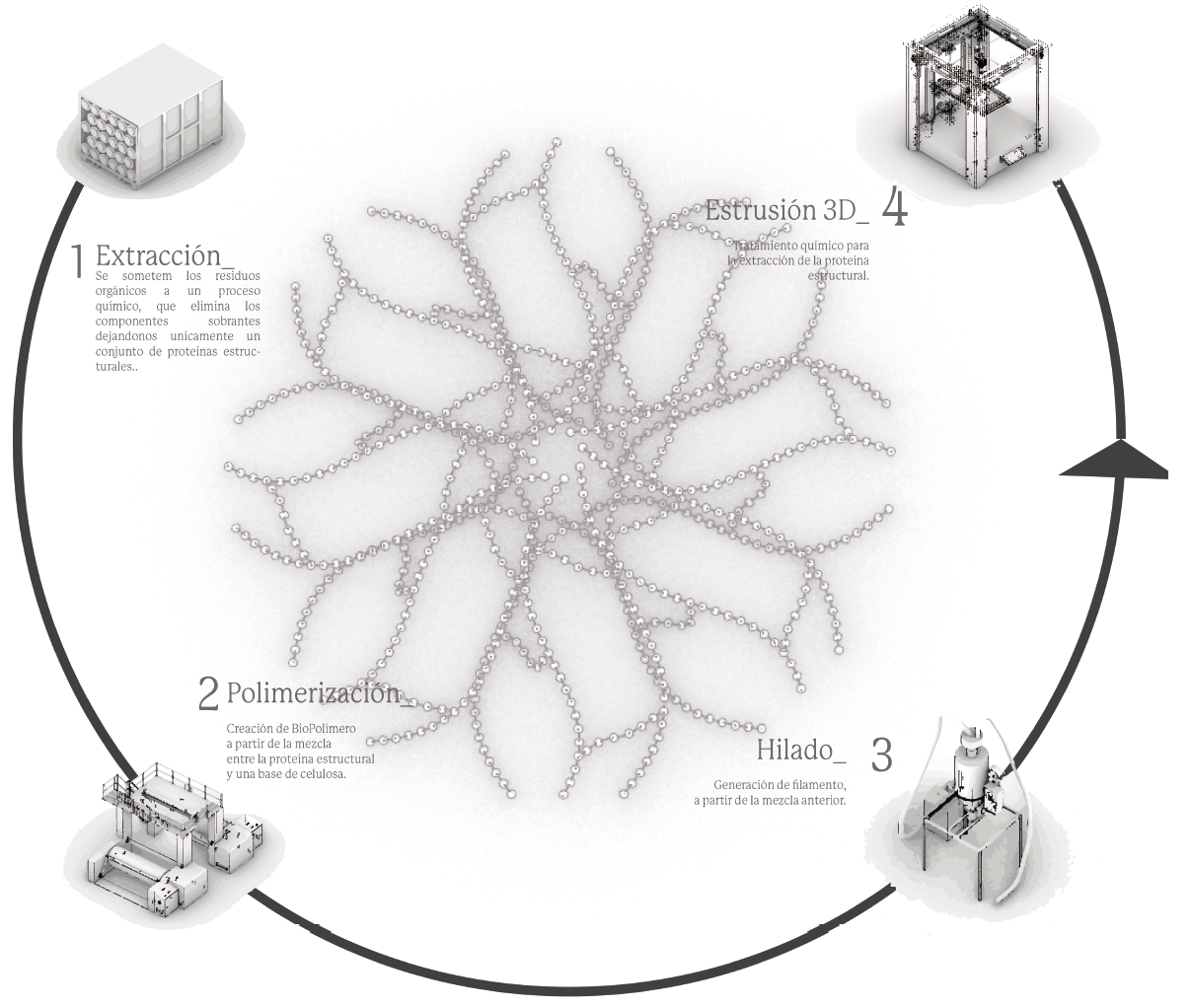

Recently at MIT, processes have been developed to manufacture biopolymers from the structural proteins contained in most of our food.

1. PECTIN is derived from plant-based foods,

2. QUITIN from seafood of animal origin, and

3. KERATIN from foods of animal origin from the land.

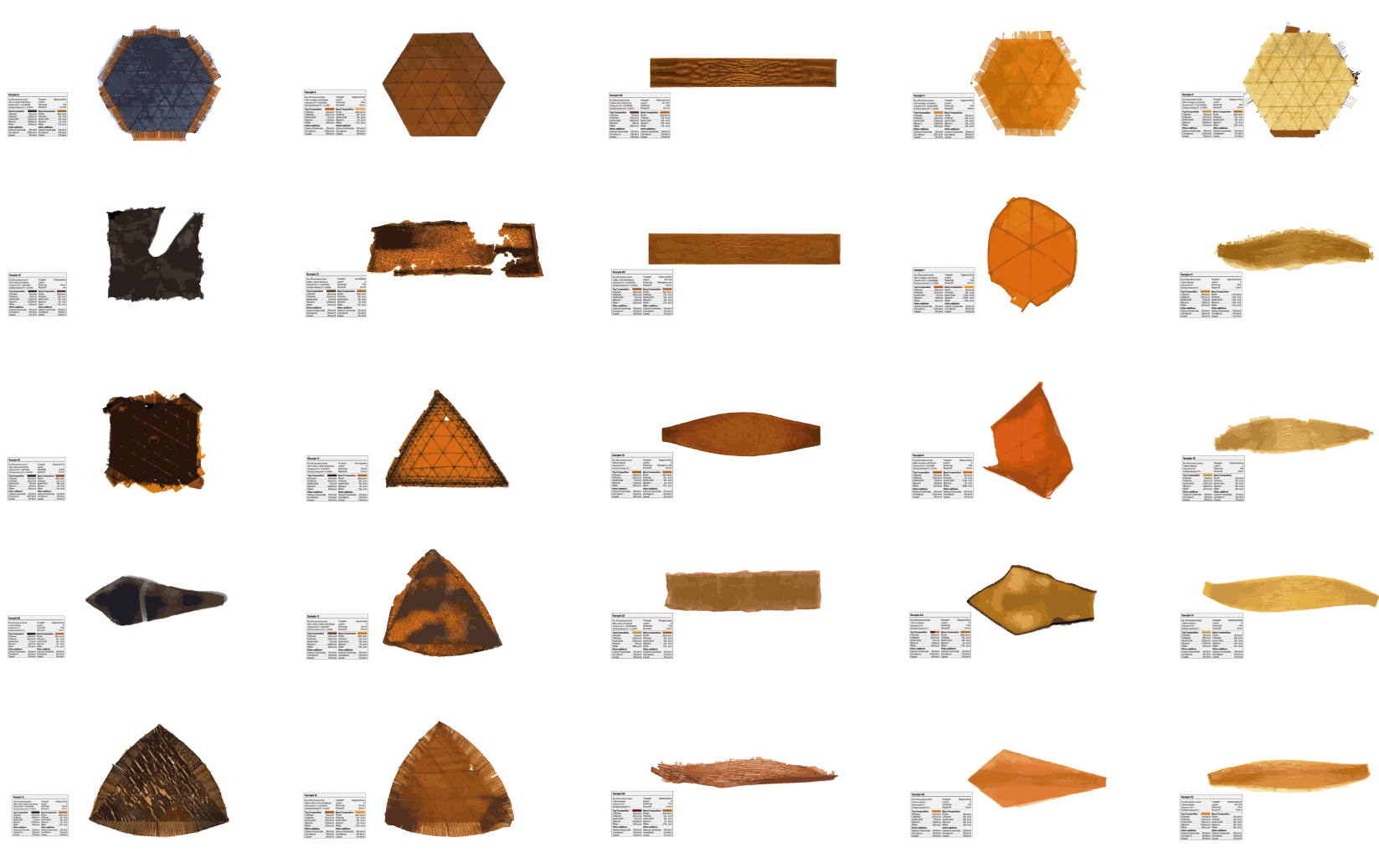

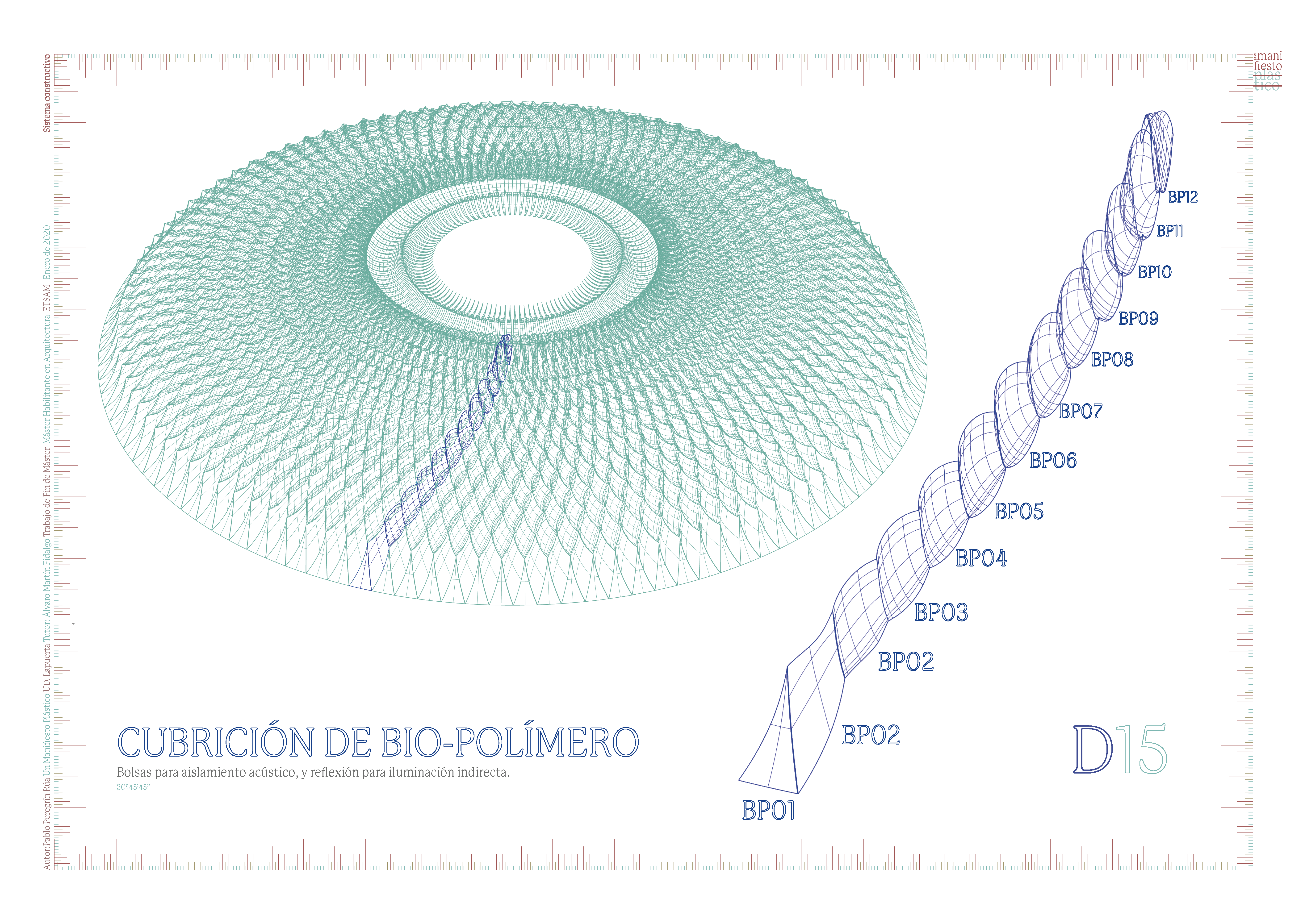

After that, they are crushed and synthesised with other components to create a BIOPOLYMER that is arranged in a filament, which we will use to extrude it in 3D at high speed. In this way we will obtain all the necessary packaging for the products offered on the market and some infrastructural elements of the future market.

We thus create a circular economy that will allow us to eliminate all the associated processes that constitute 70% of the impact of the current industry, where waste is the input for the production of new packaging.

Construction

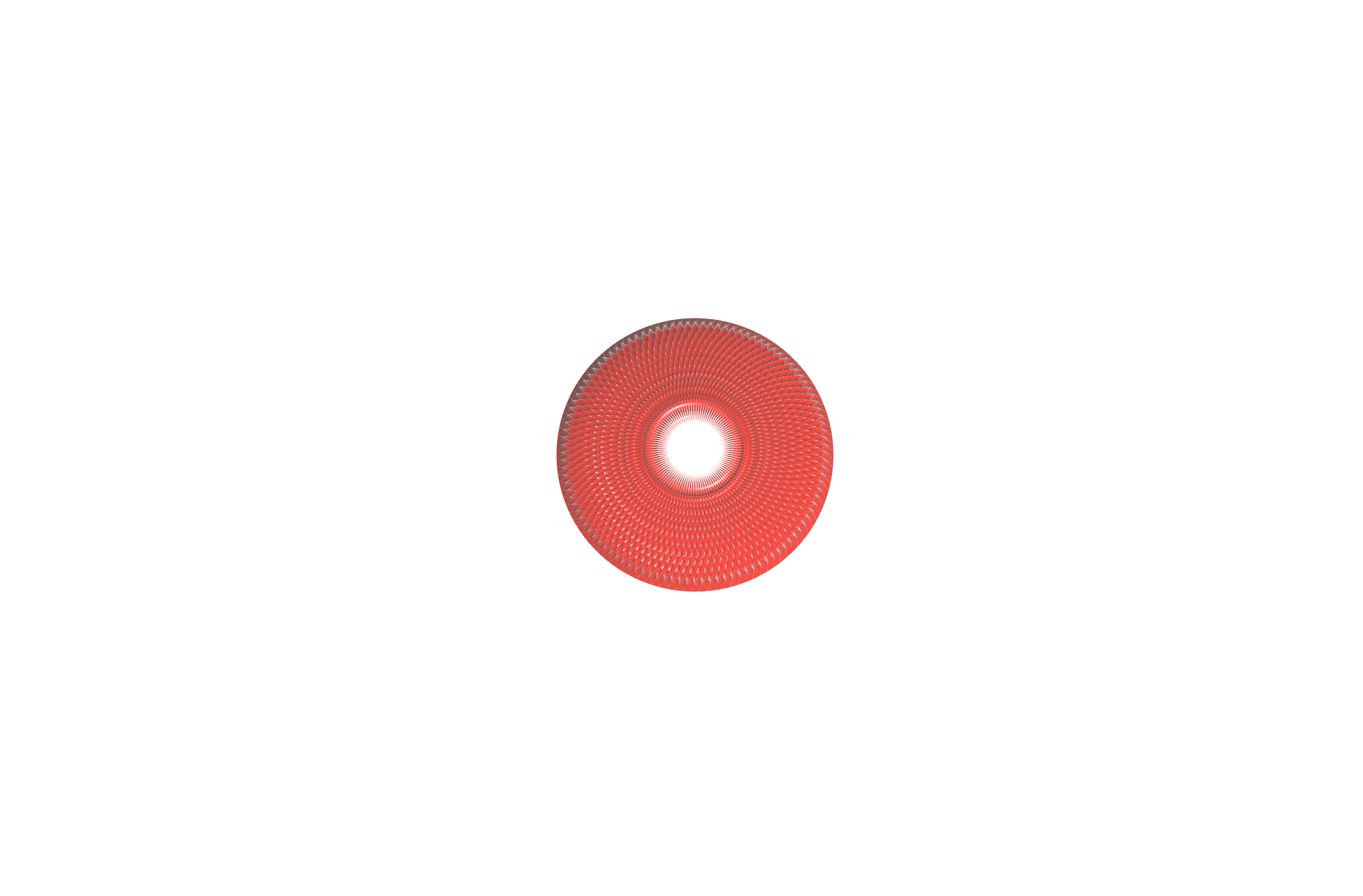

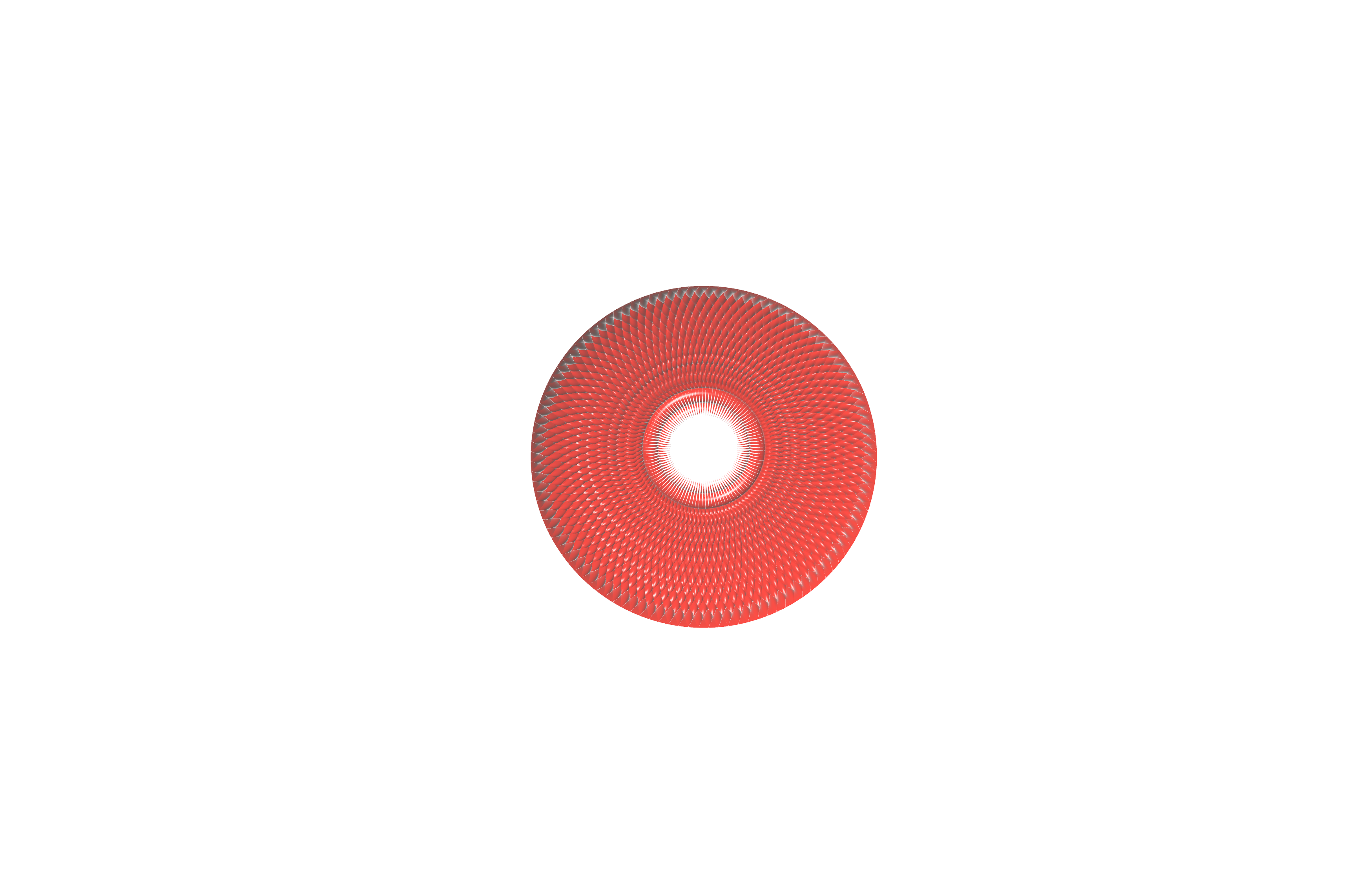

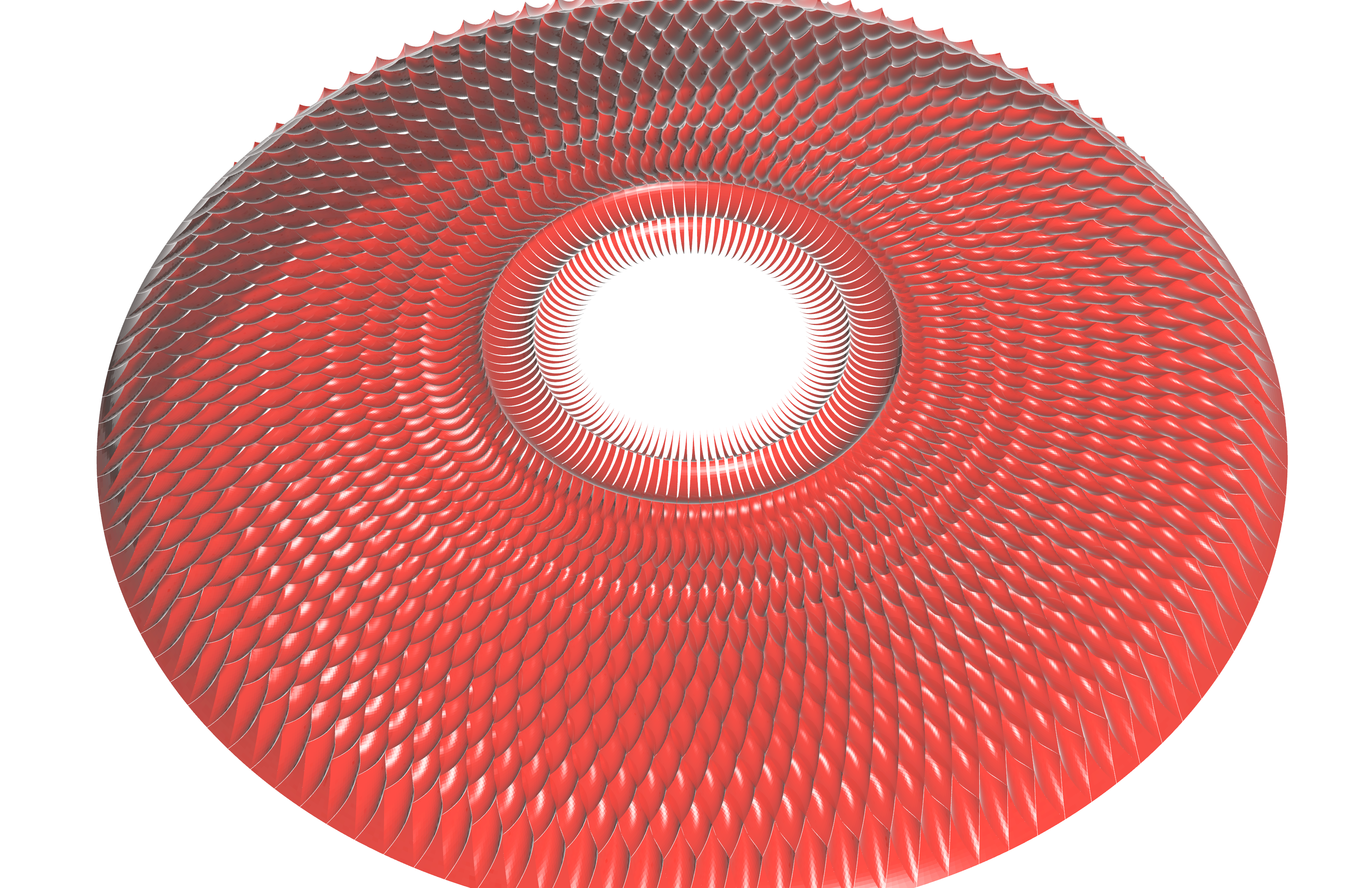

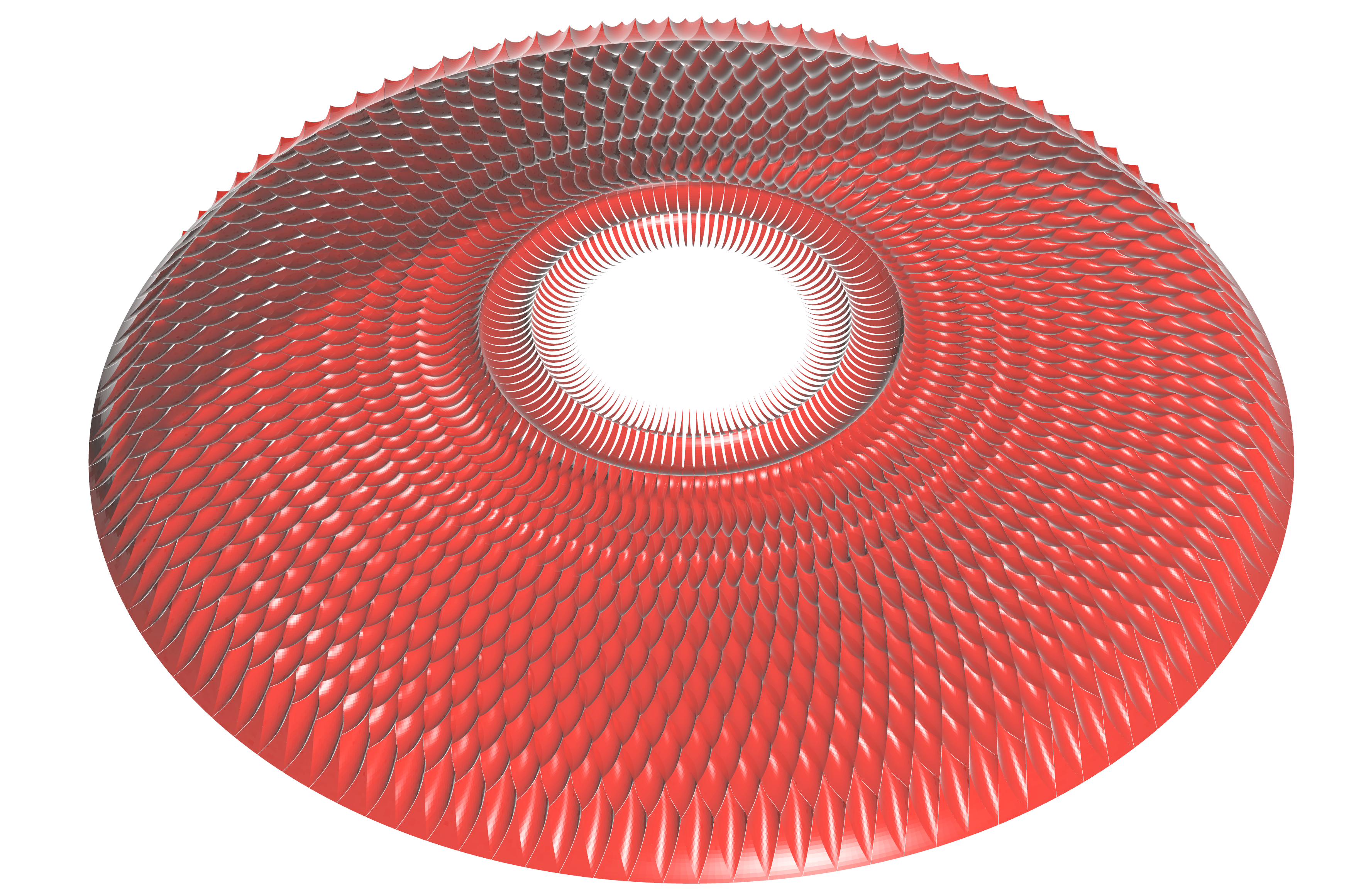

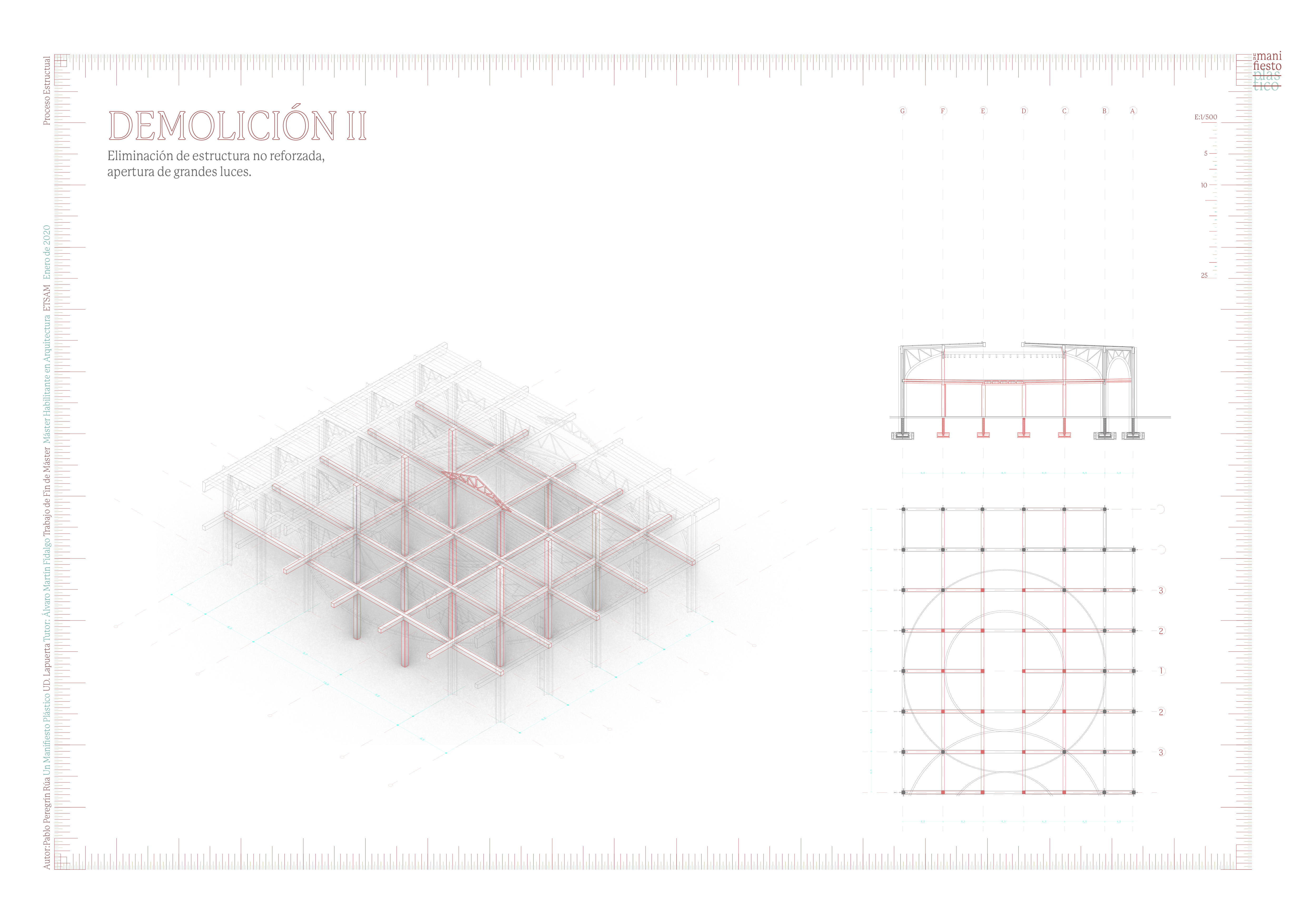

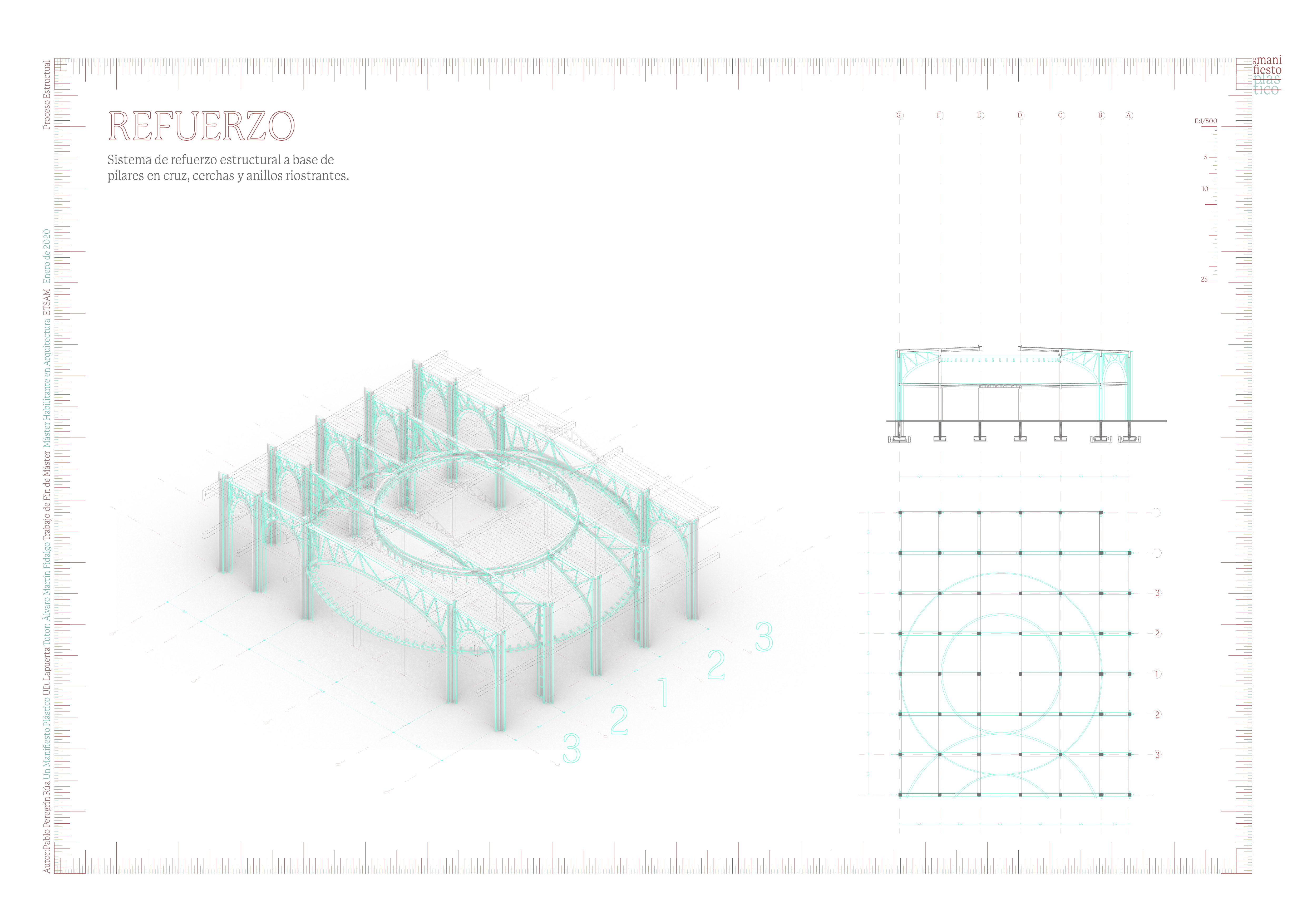

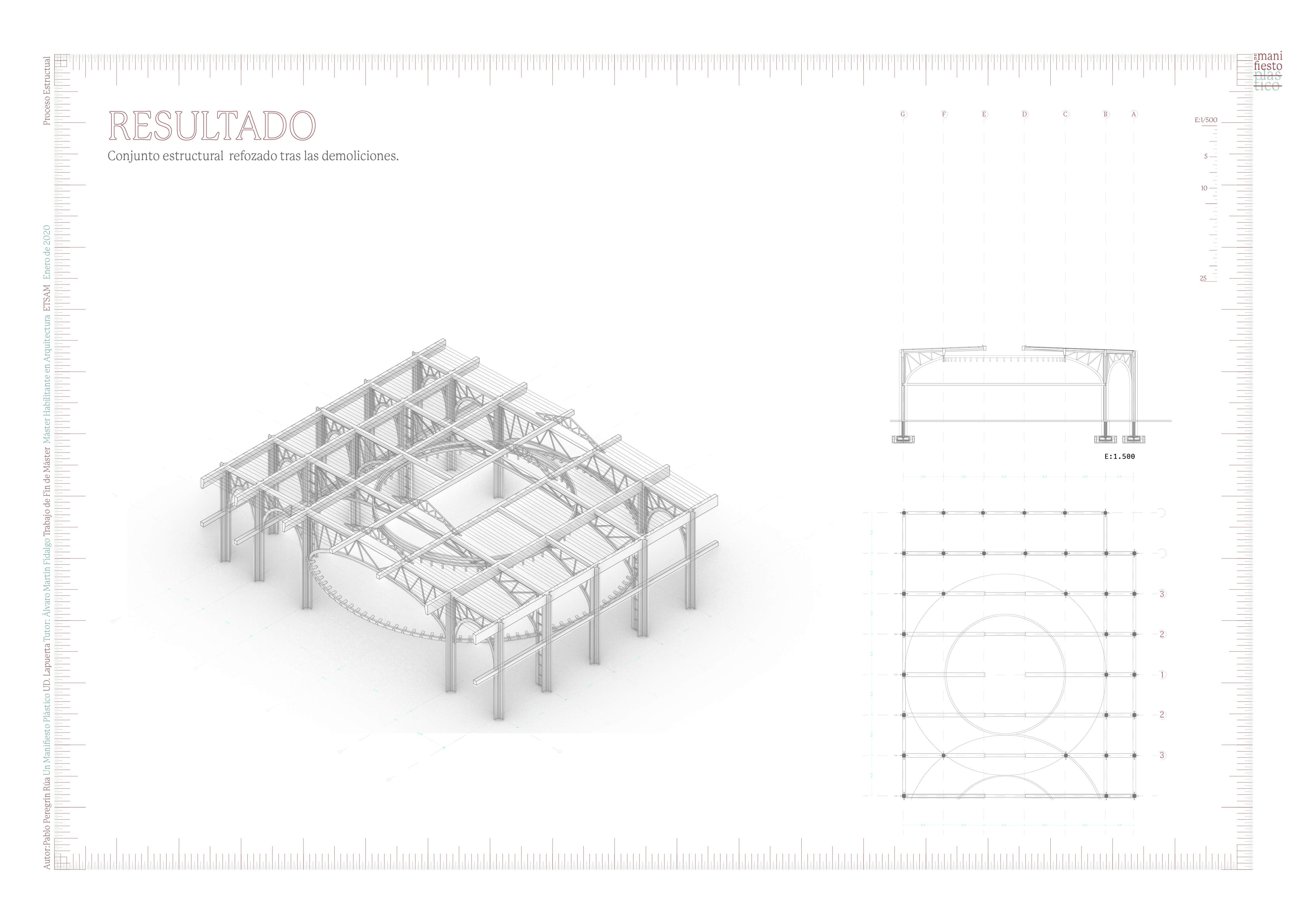

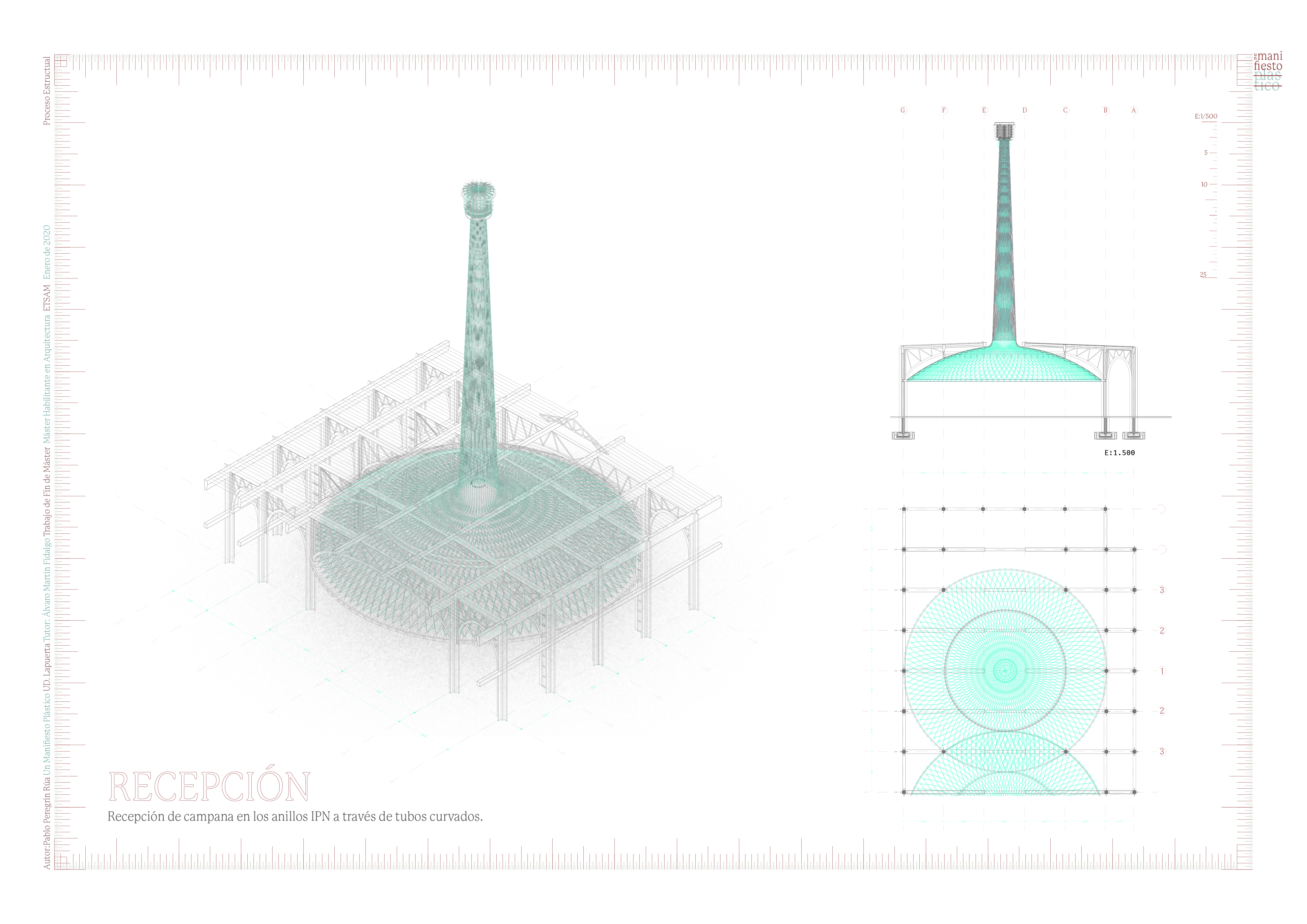

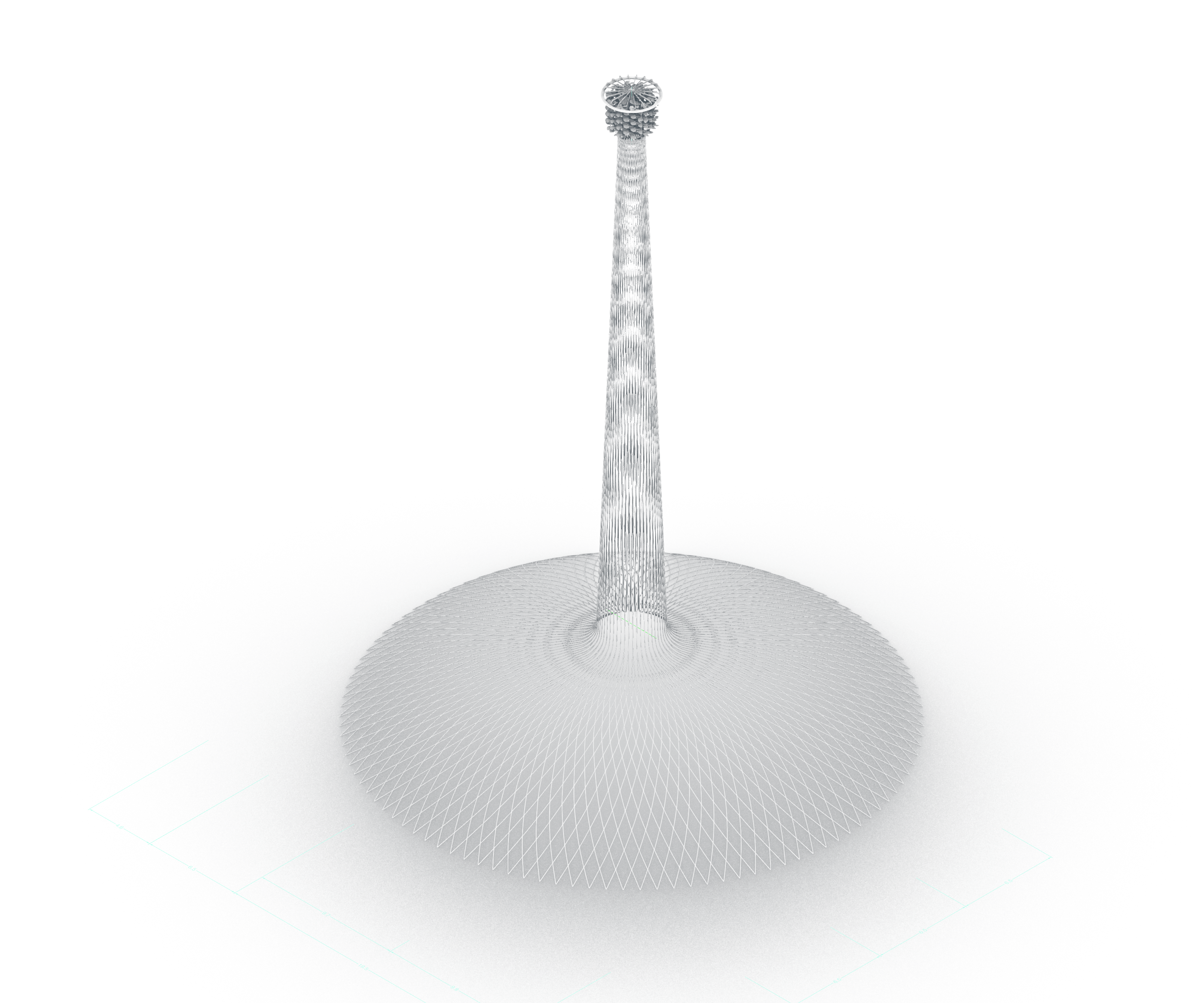

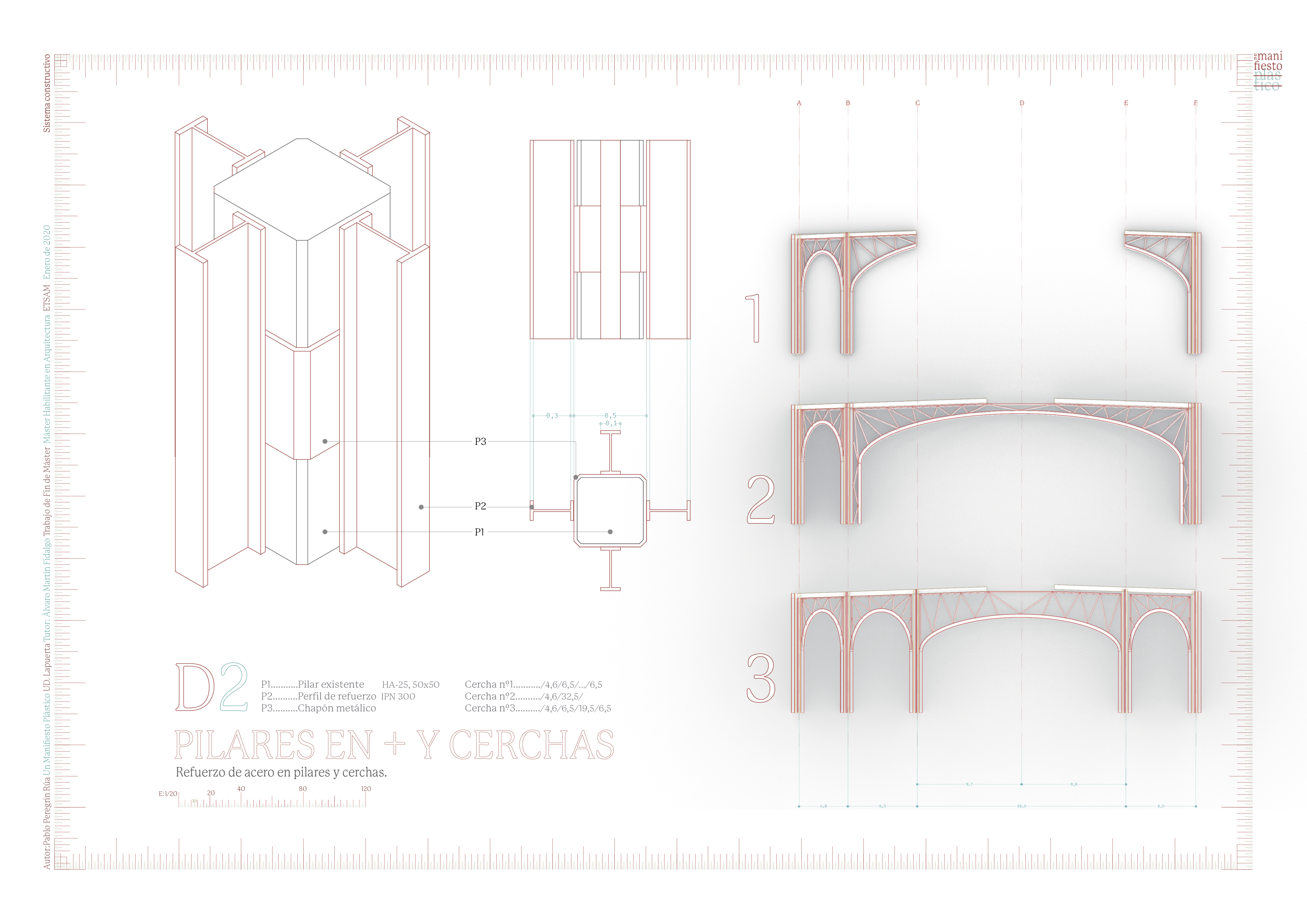

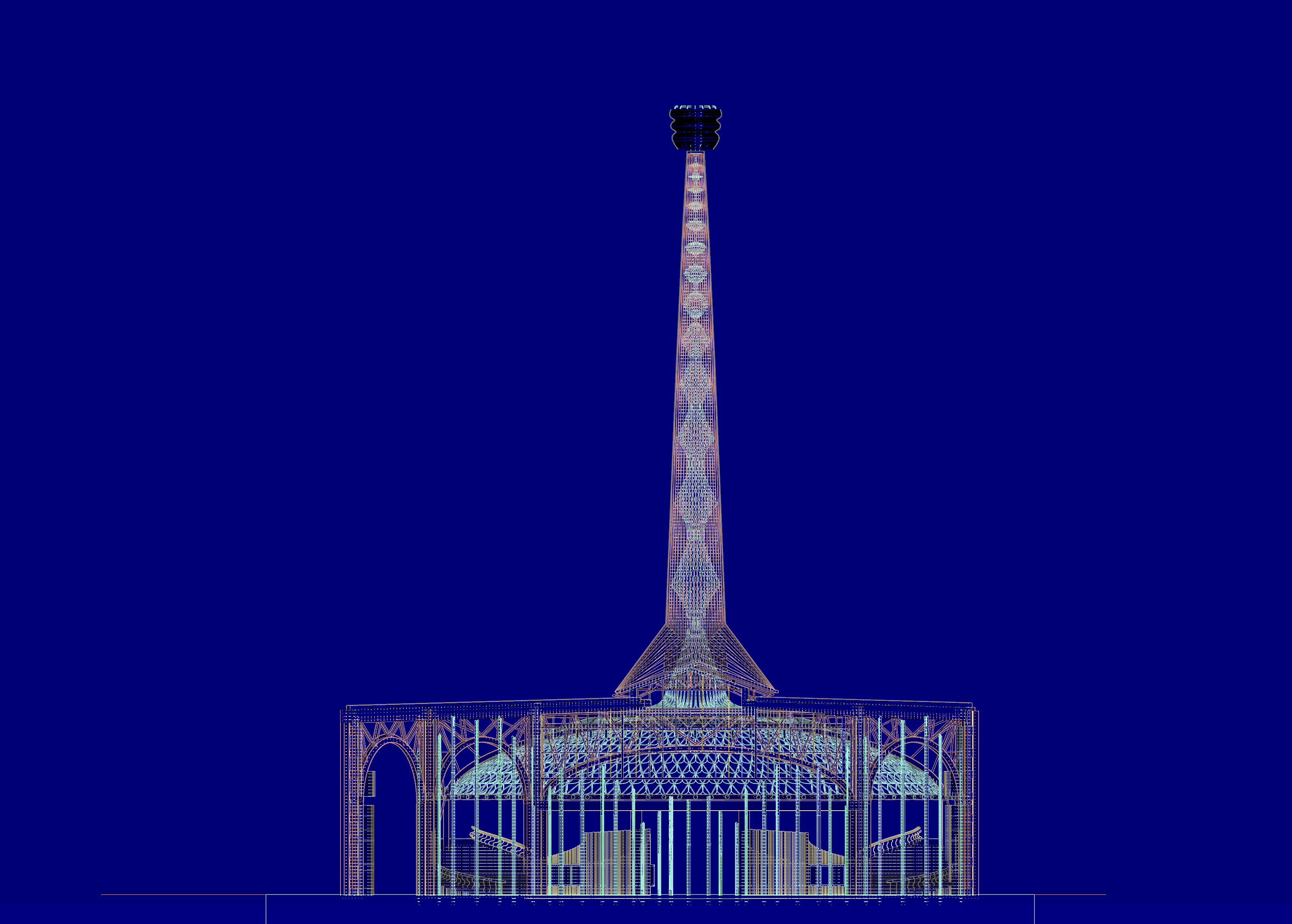

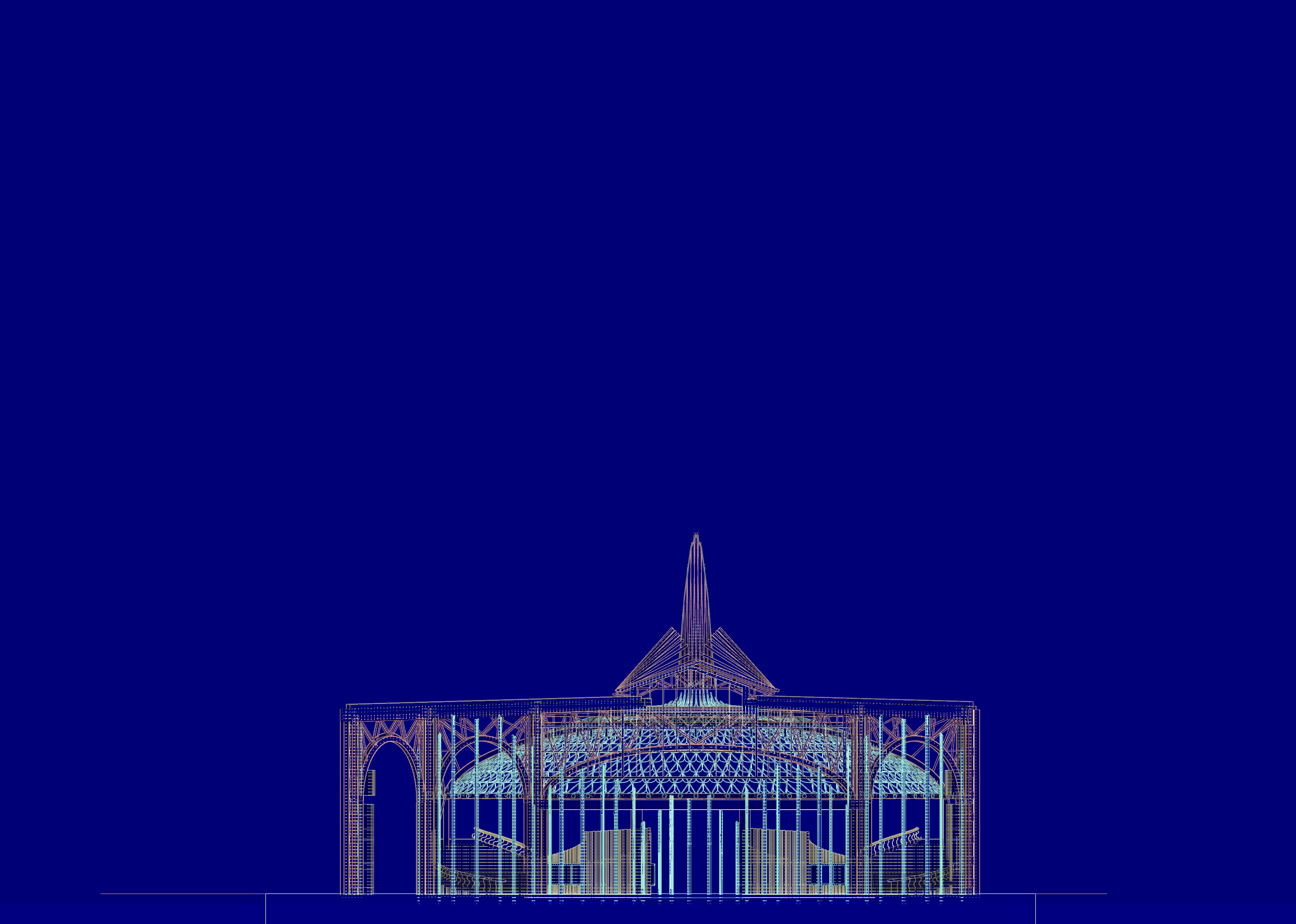

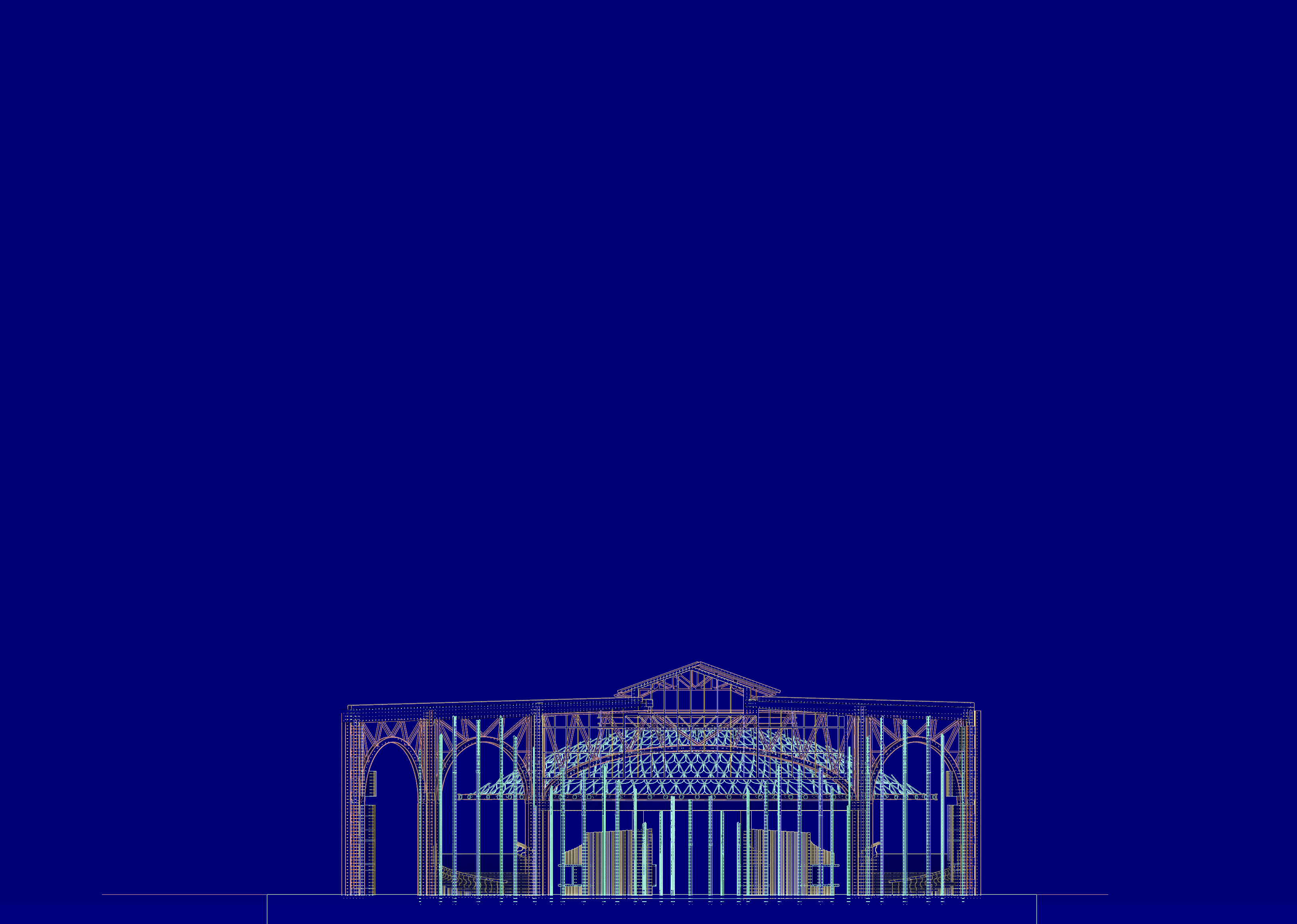

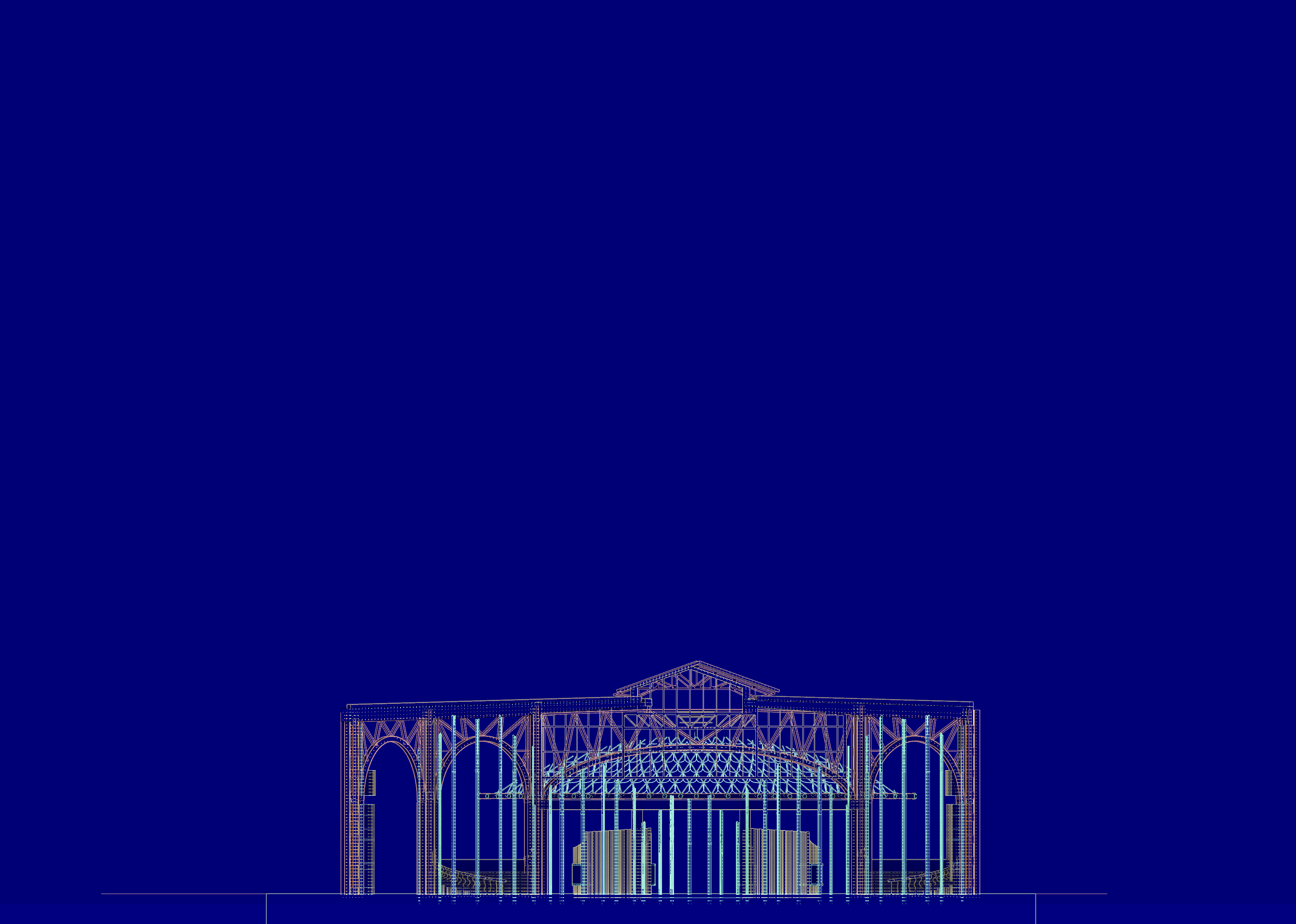

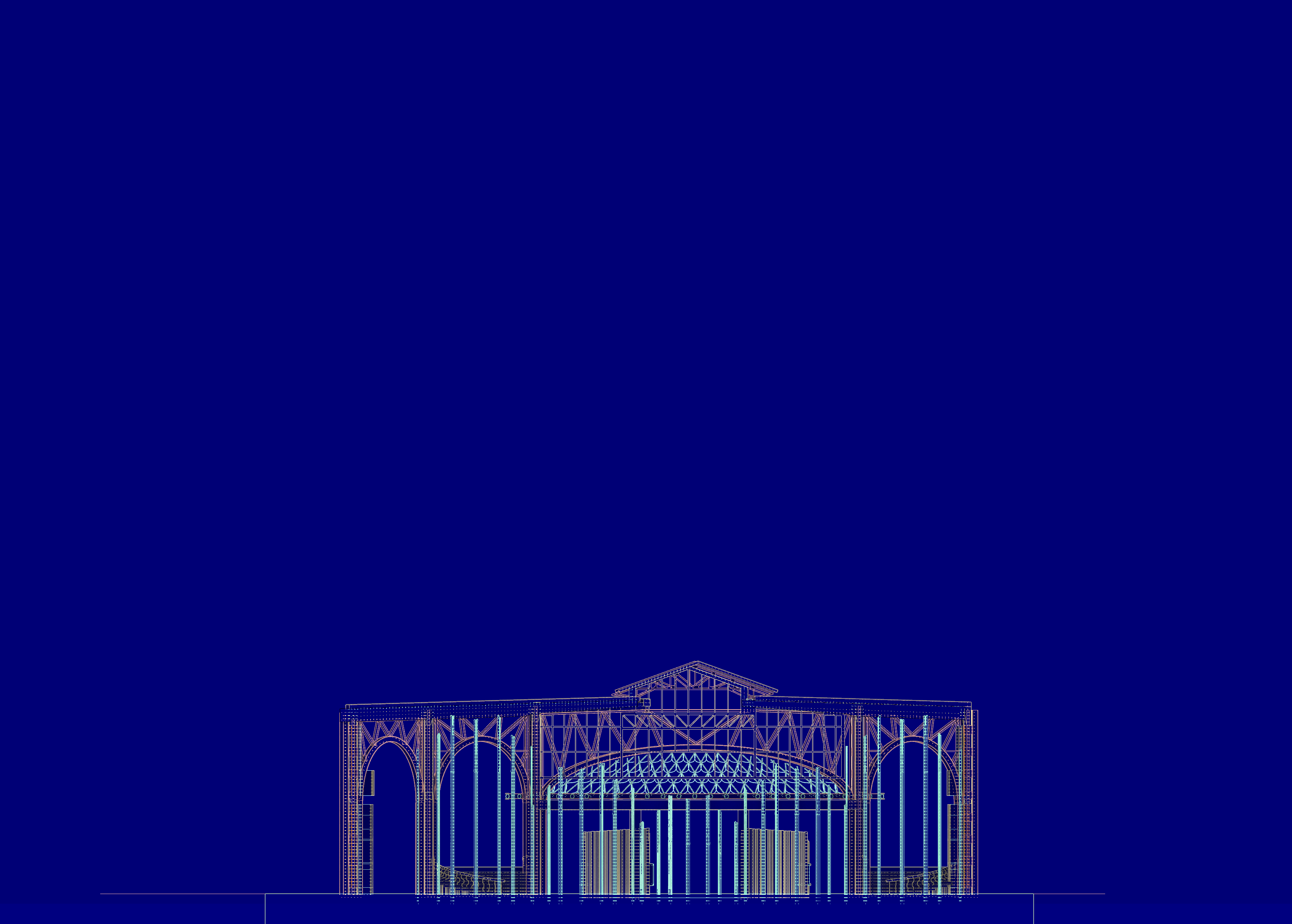

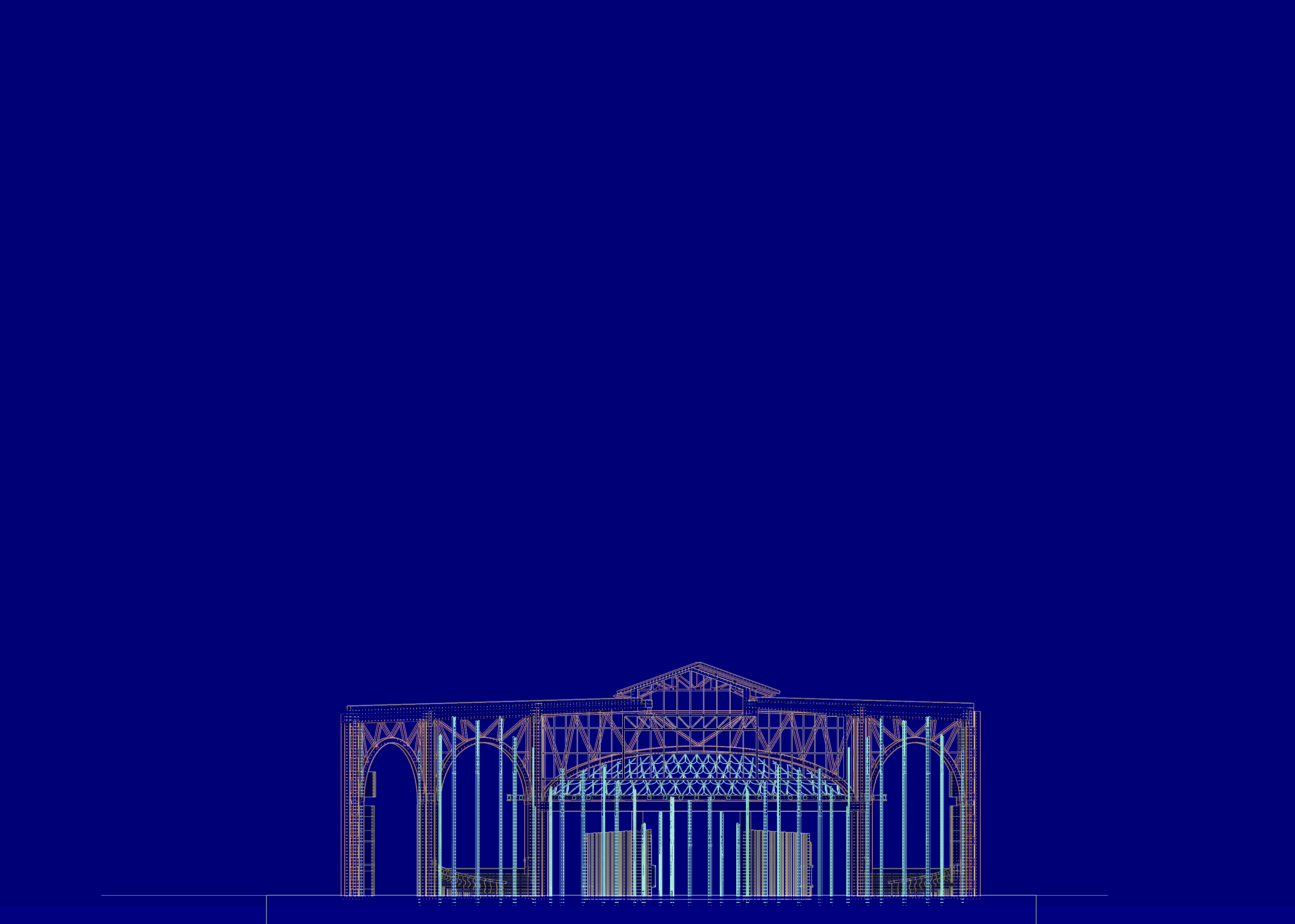

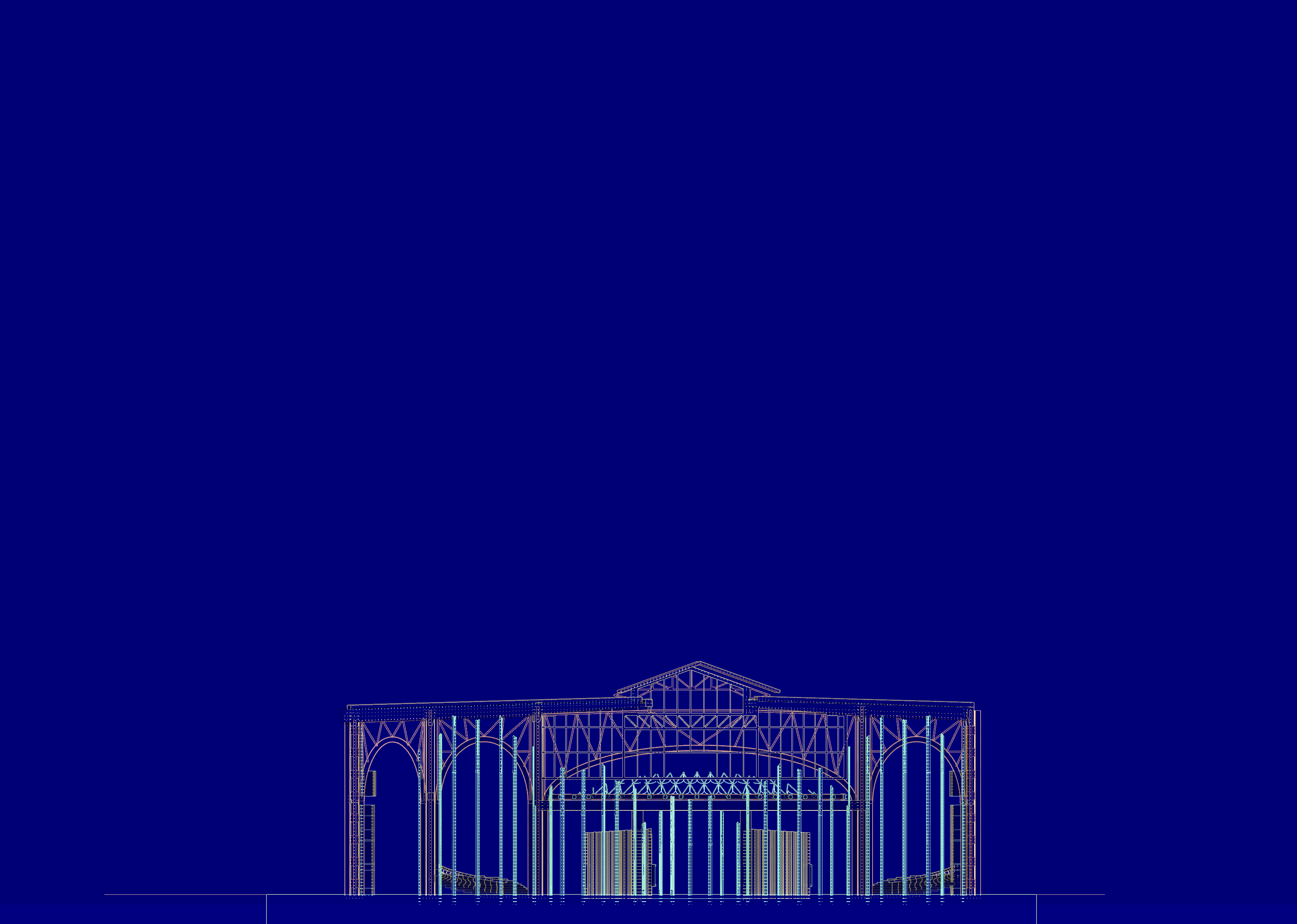

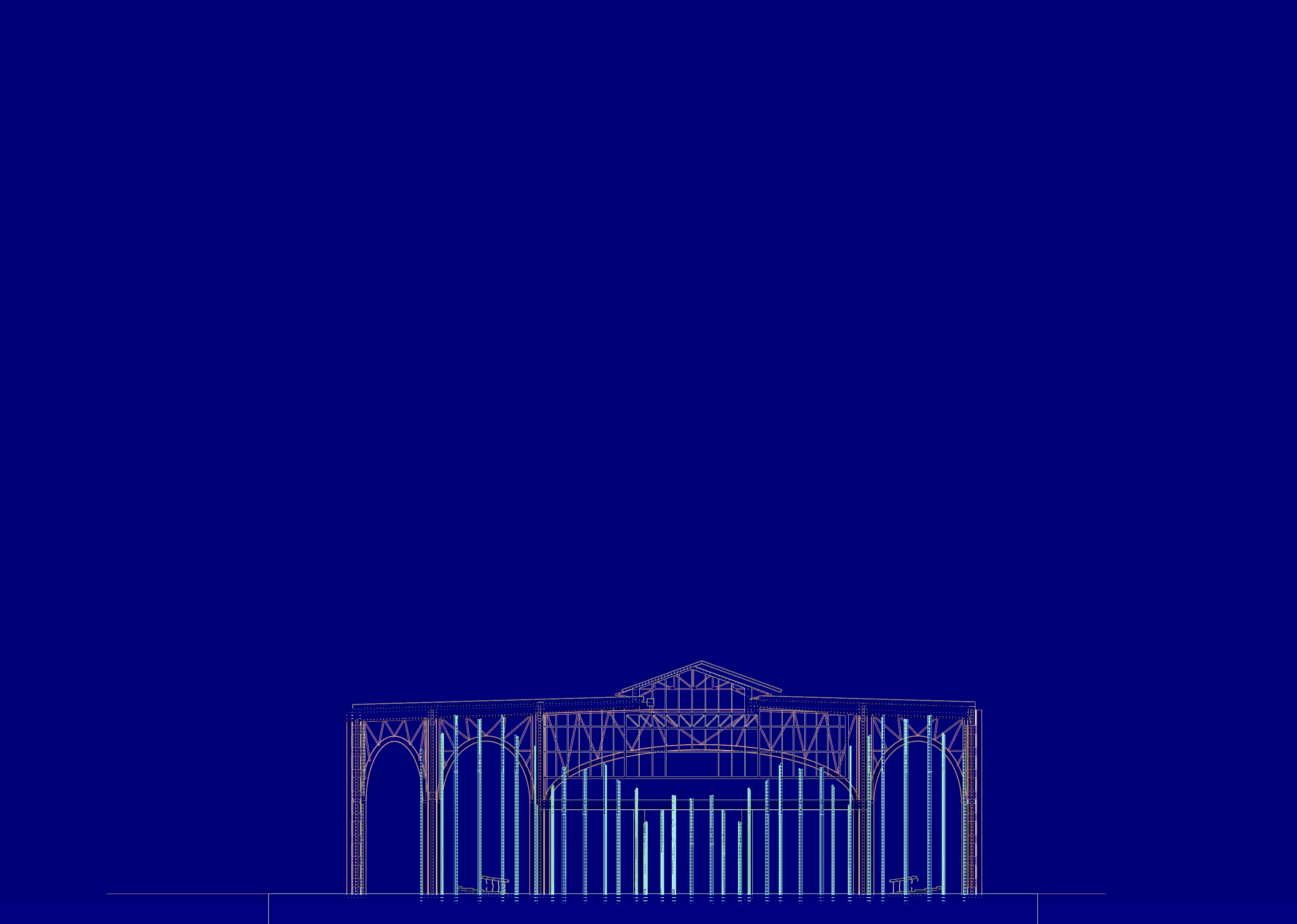

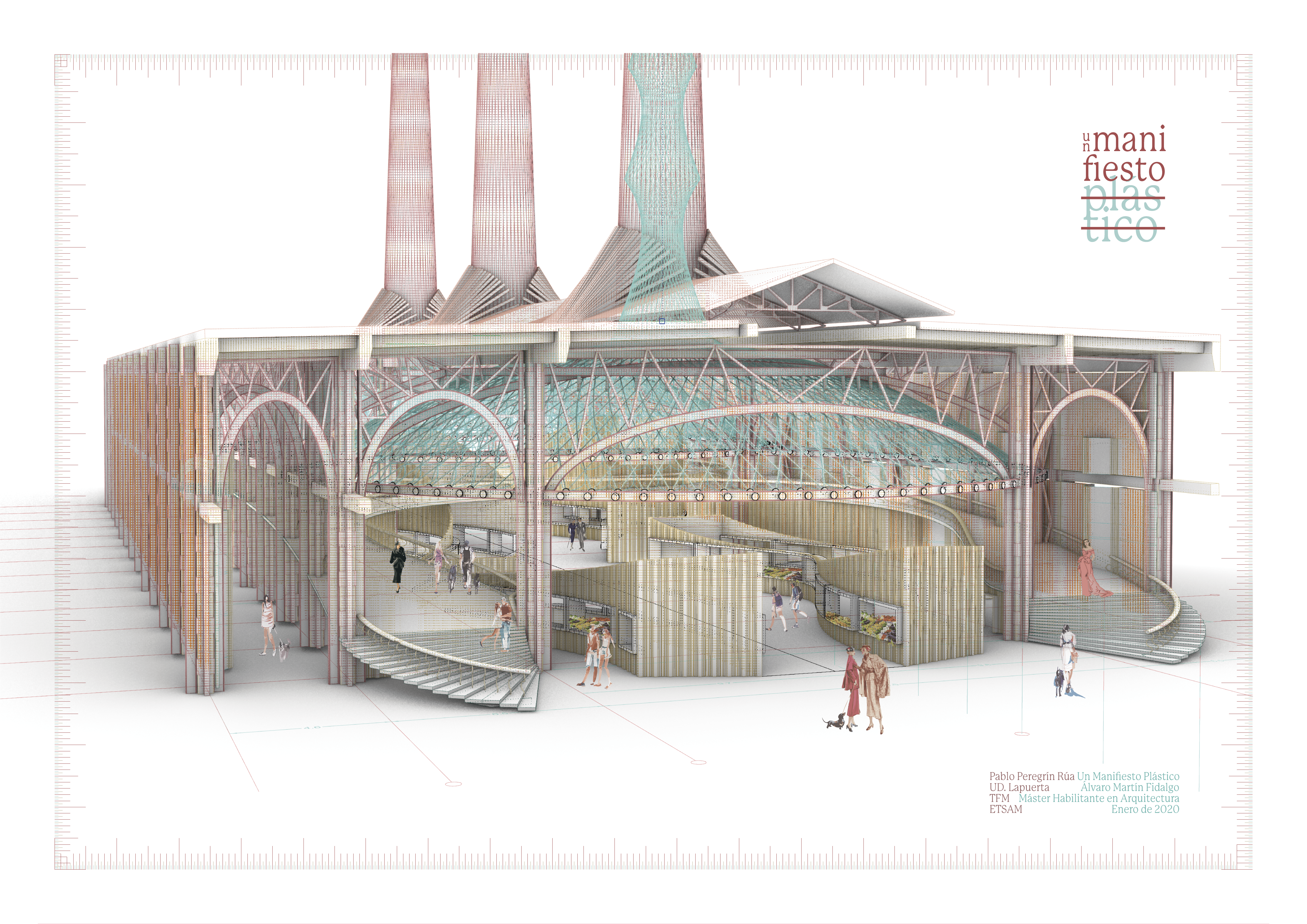

We will reinforce the bays with three configurations, arranged in sequence 3, 2, 1, 2, 3, creating a space capable of accommodating a spherical cap. Mass-produced prefabricated and dry-joint construction systems will be used, safeguarding the environmental impact of the construction process.

The pillars will be reinforced with steel using IPN profiles placed in a cross pattern.

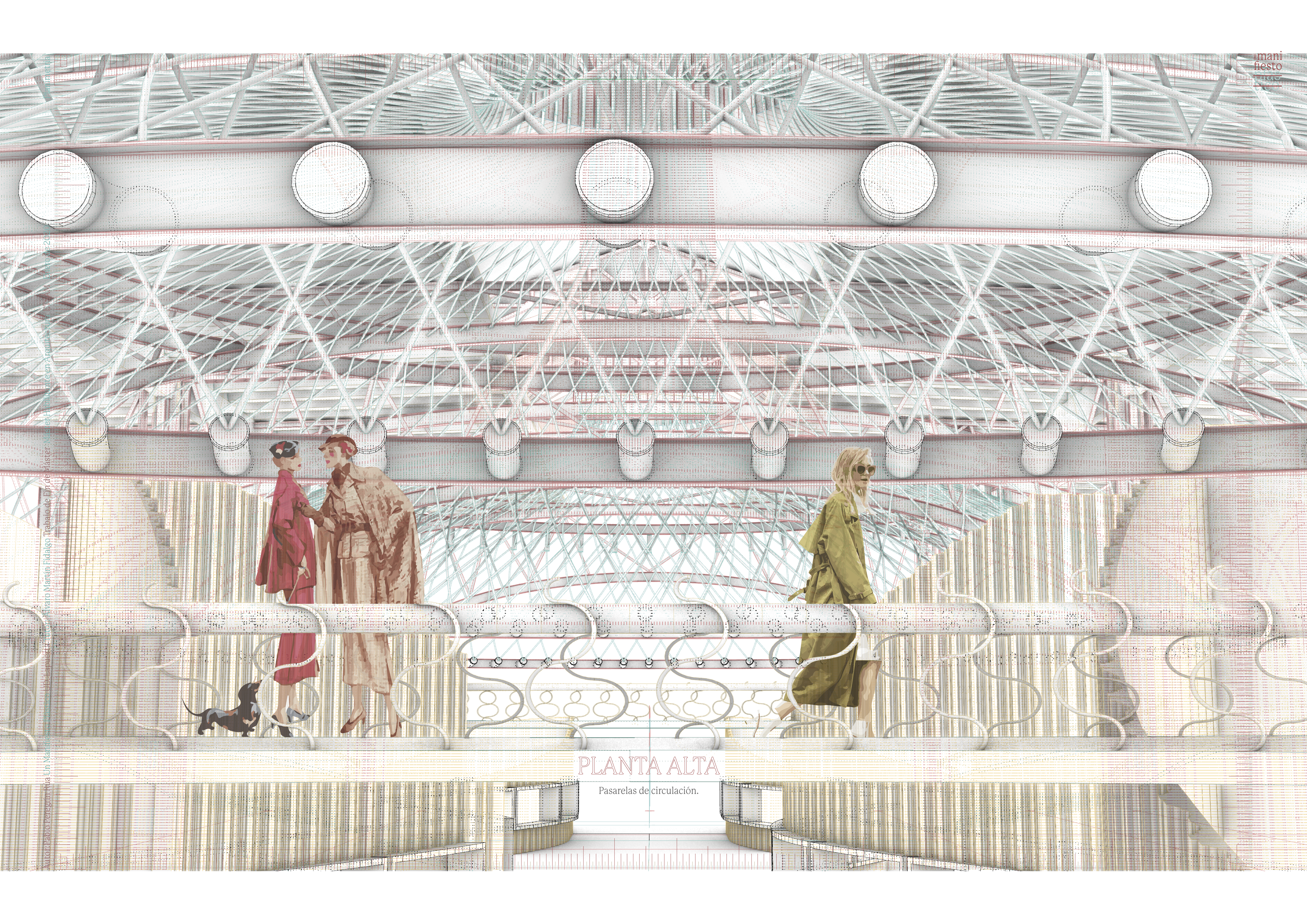

Some are extended to the roof, while others are extended to the next pillar, giving rise to the lower rib of a steel truss network.

Two rings, one at the bottom and one at the top, are placed to compensate for the bracing of the building when demolishing part of the interior structure.

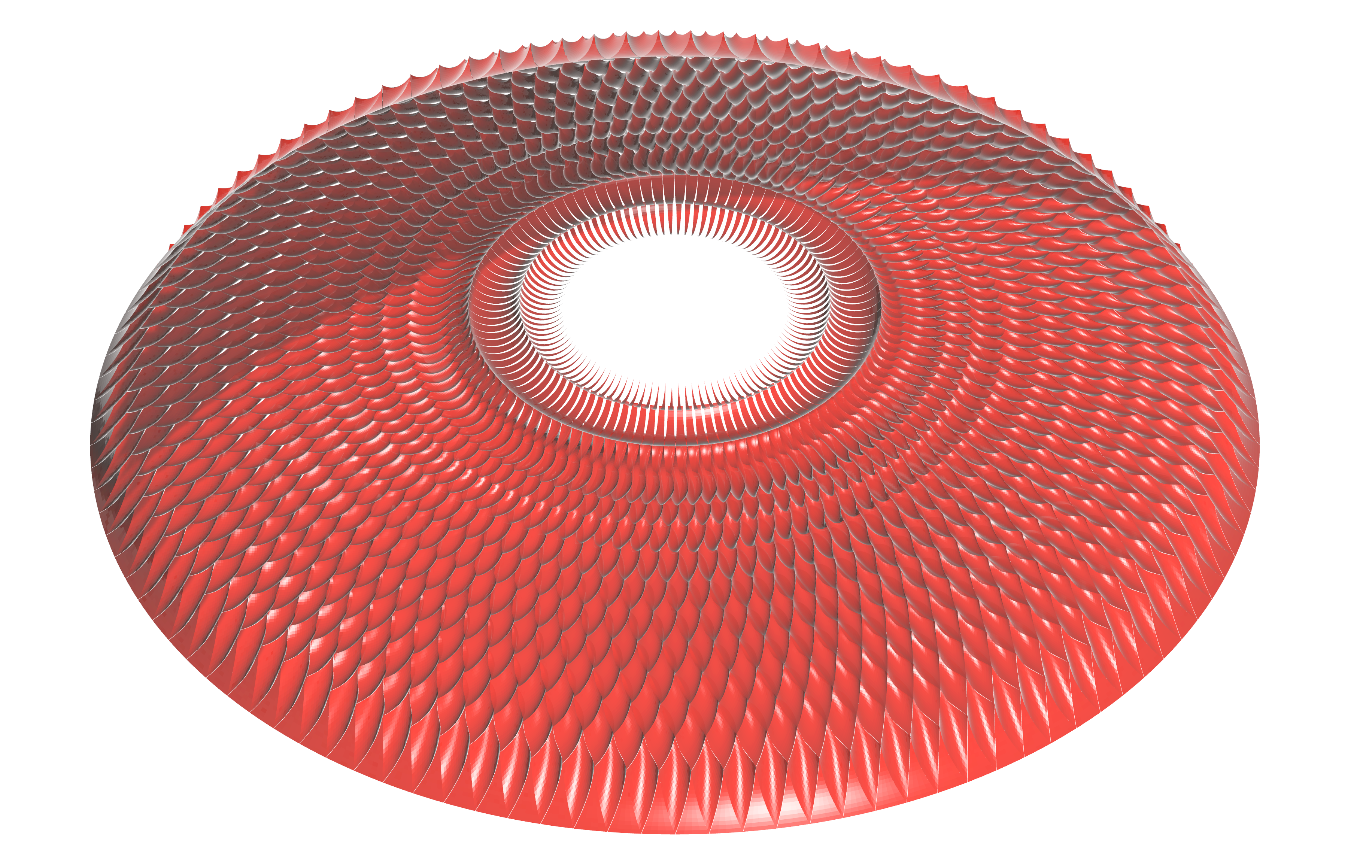

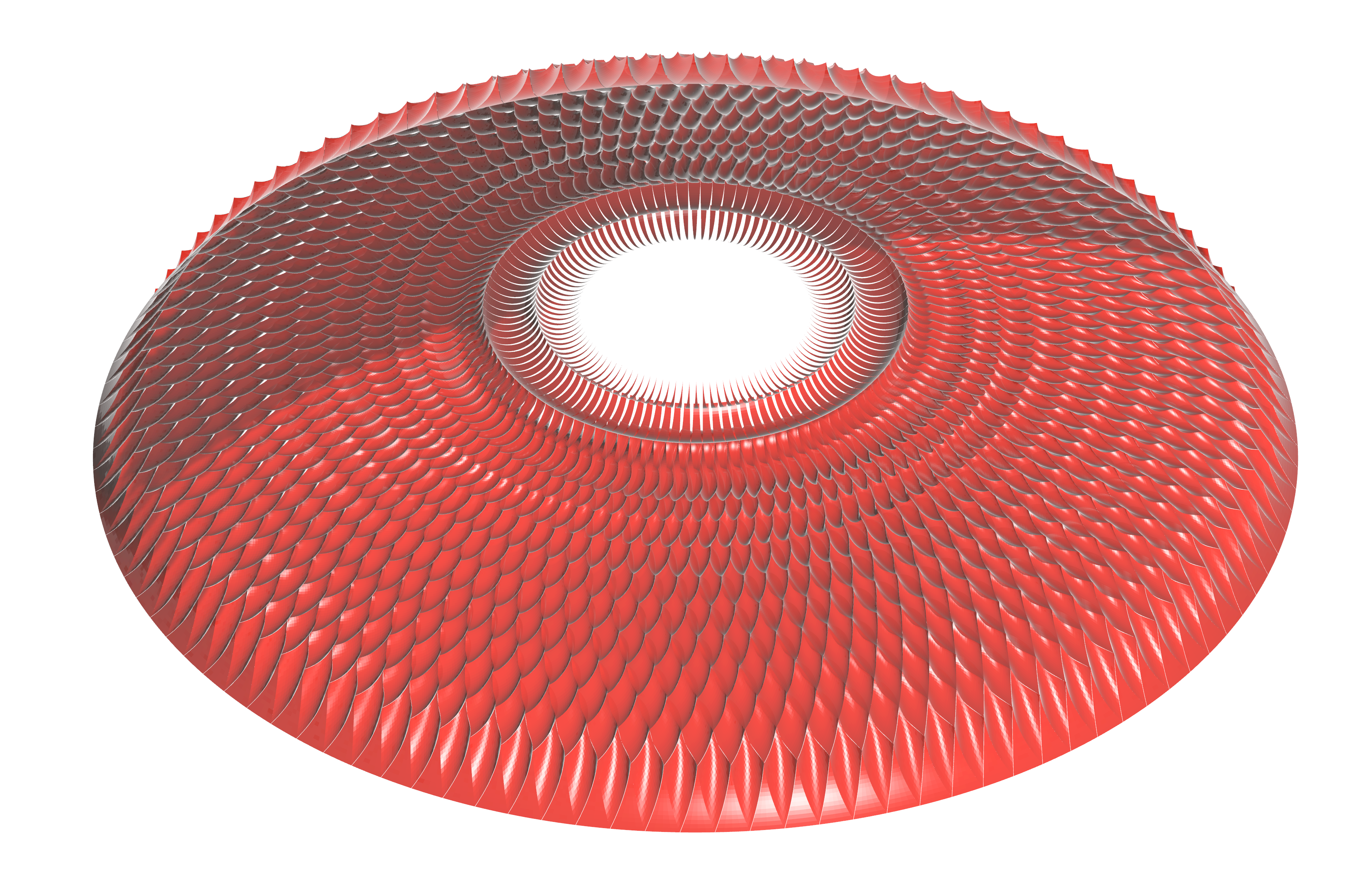

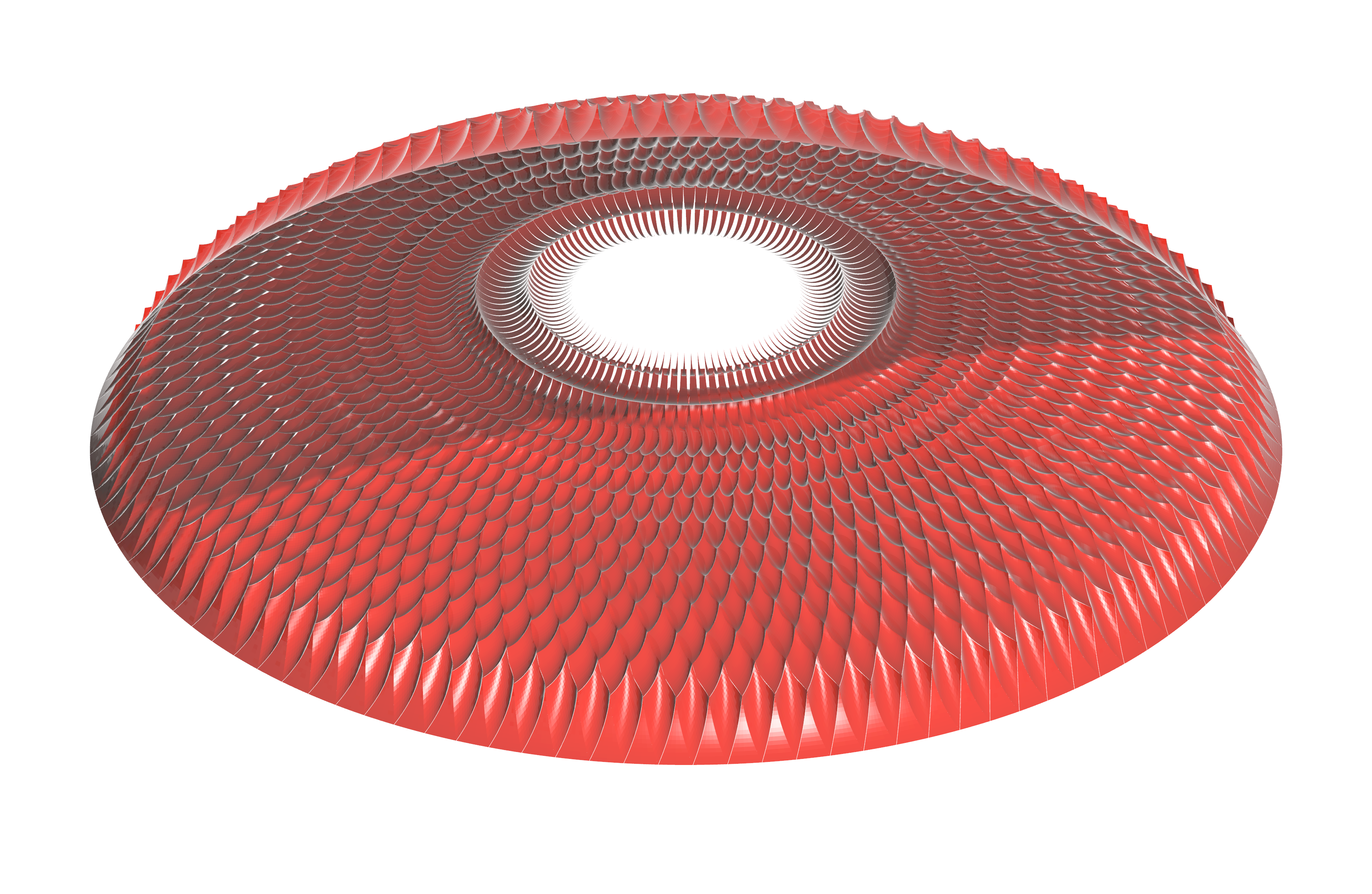

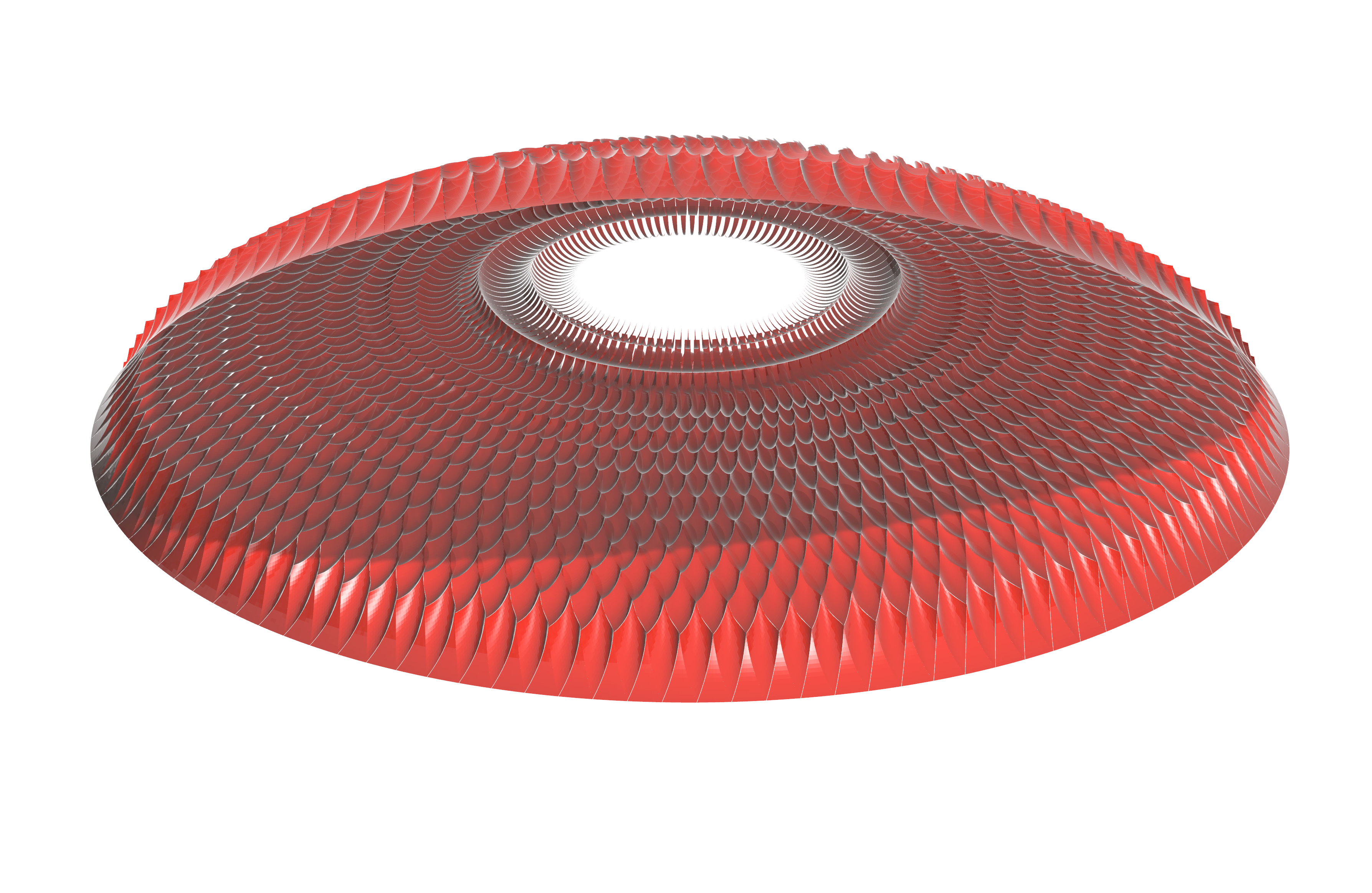

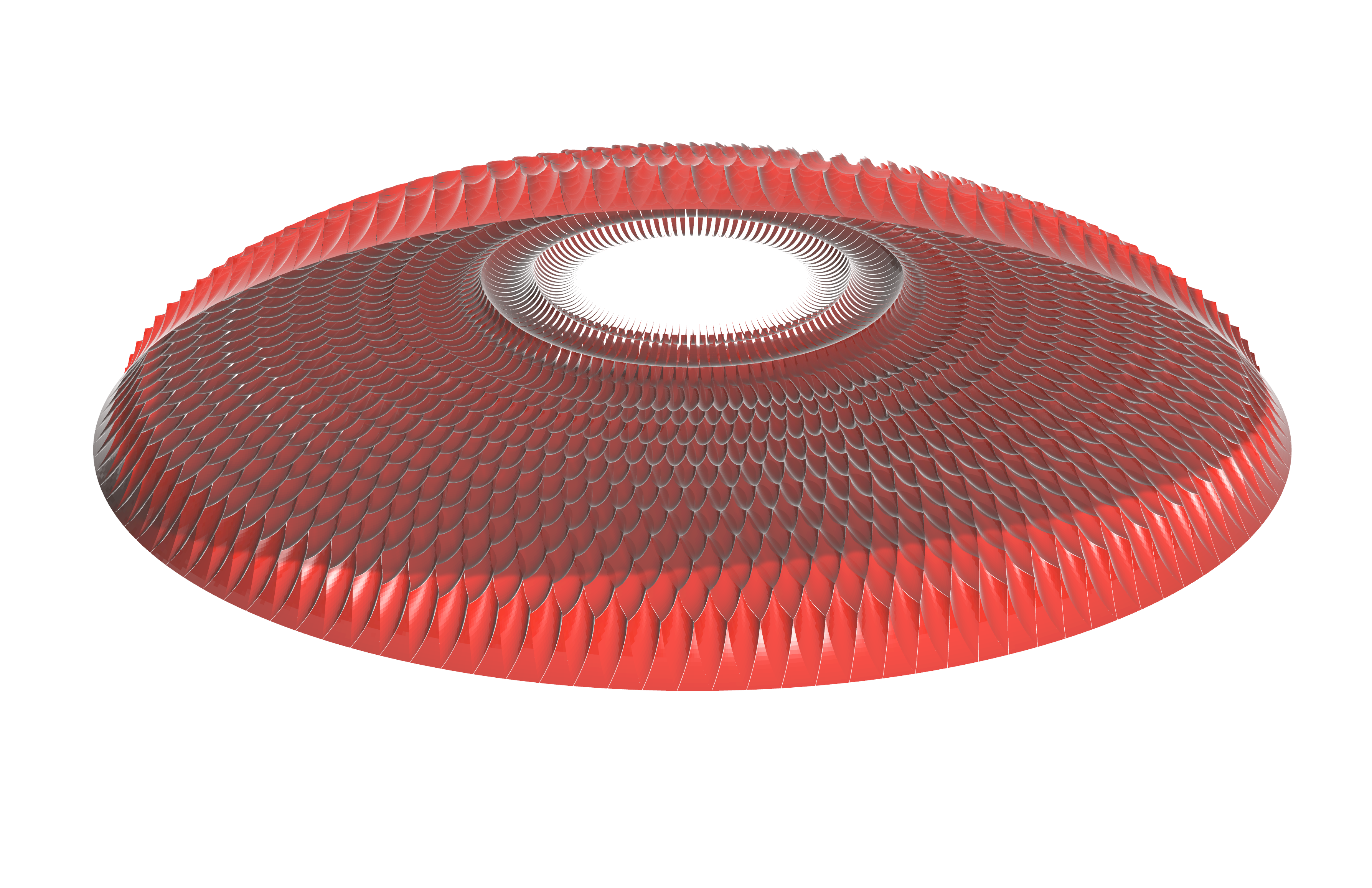

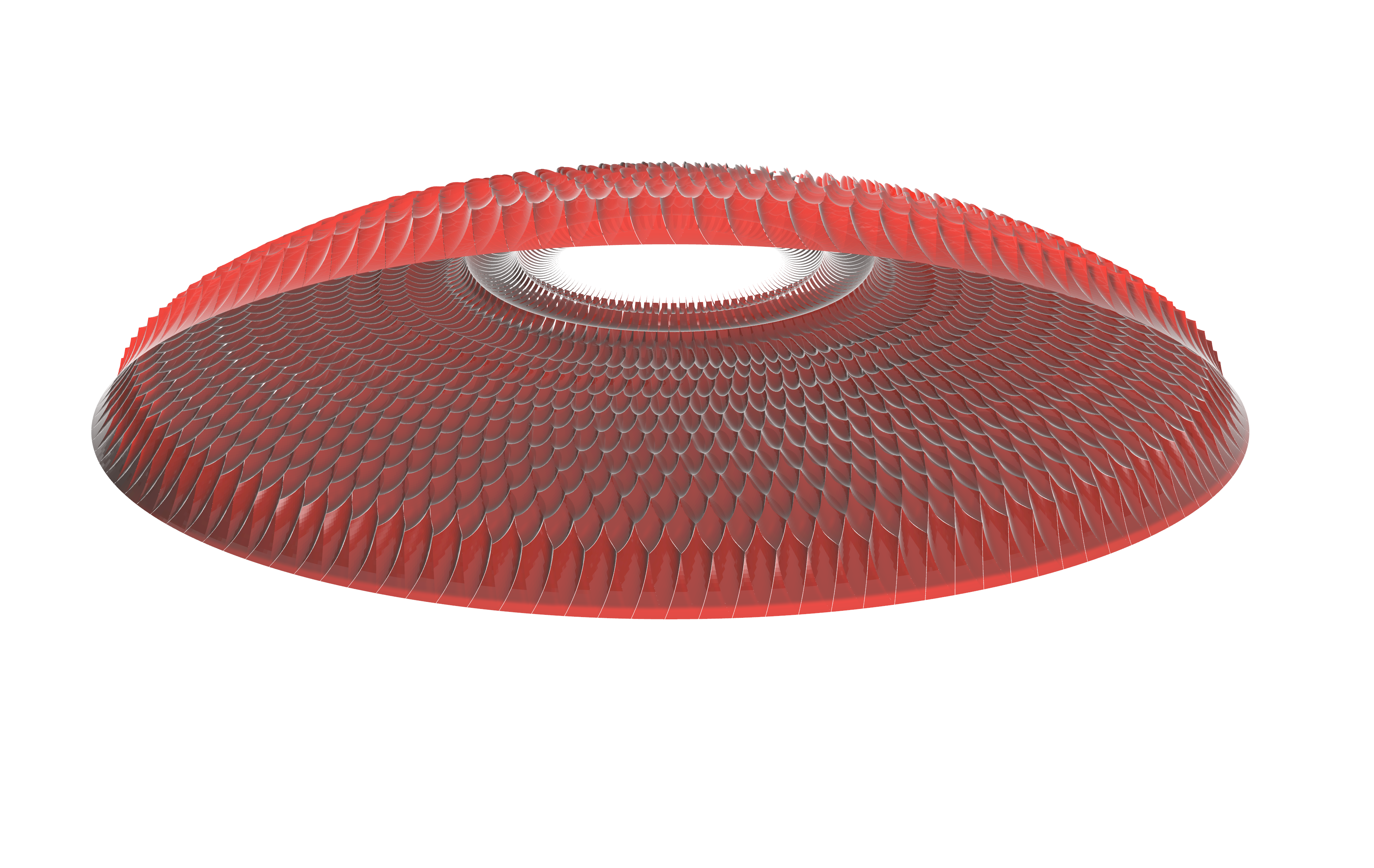

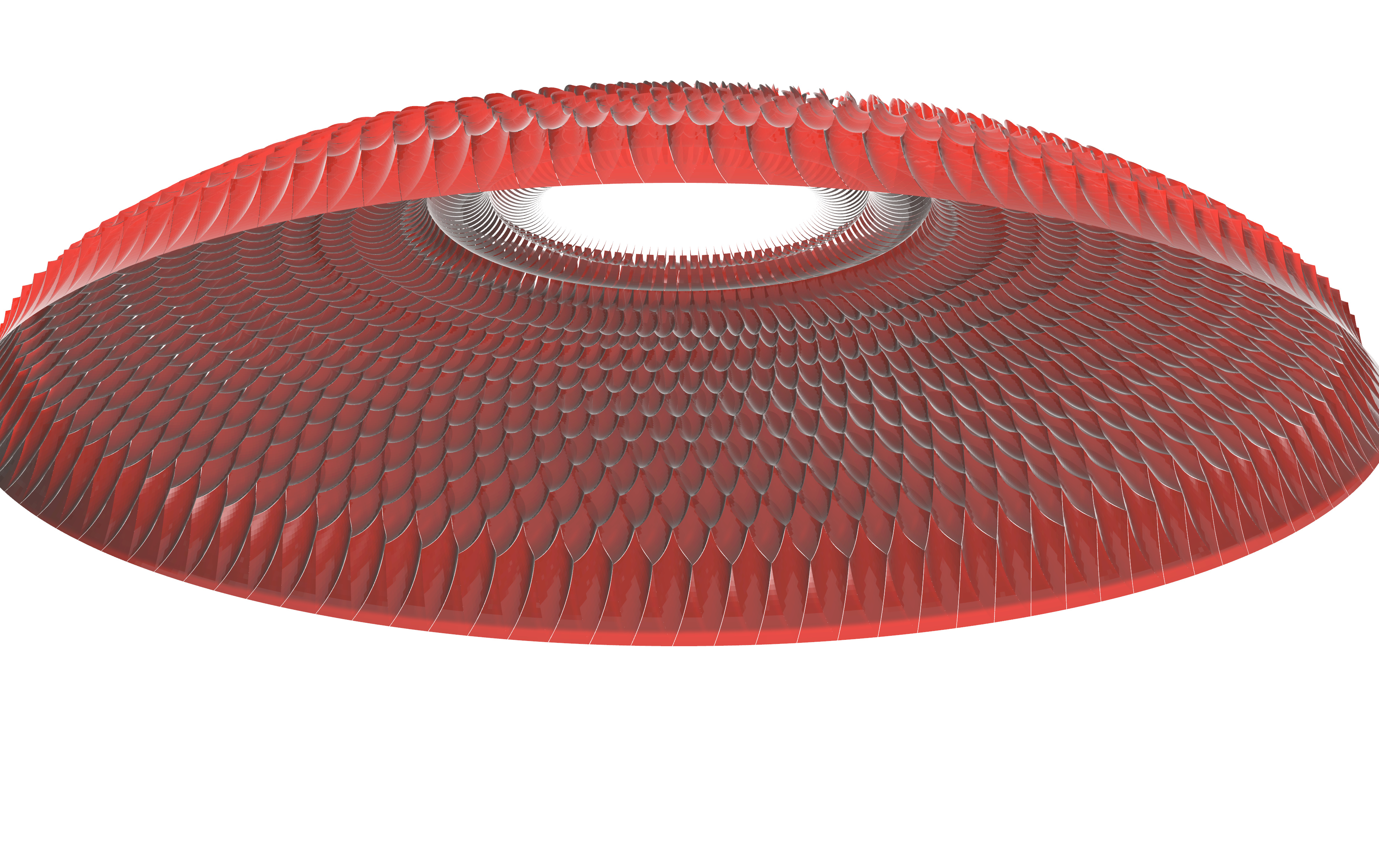

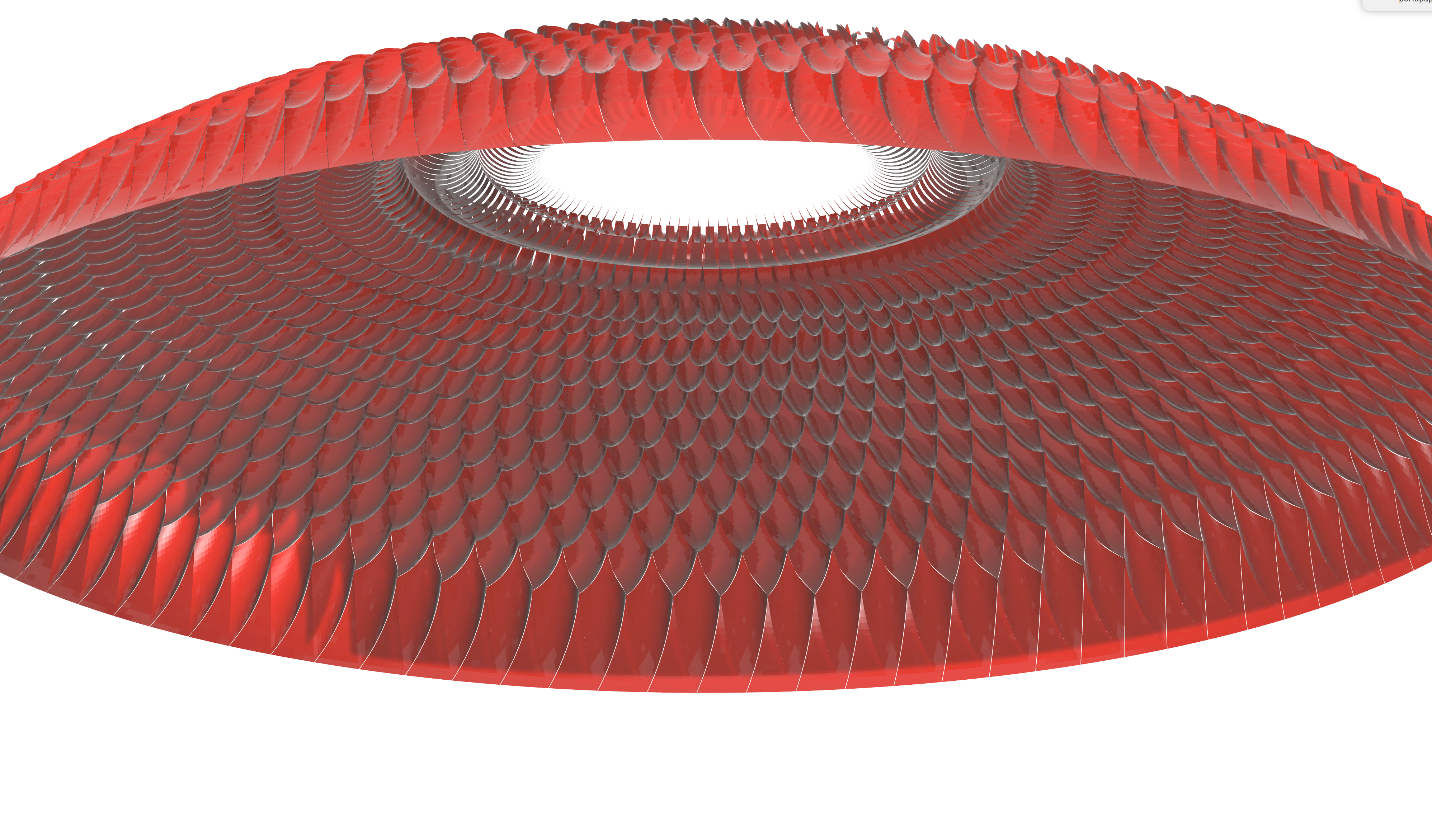

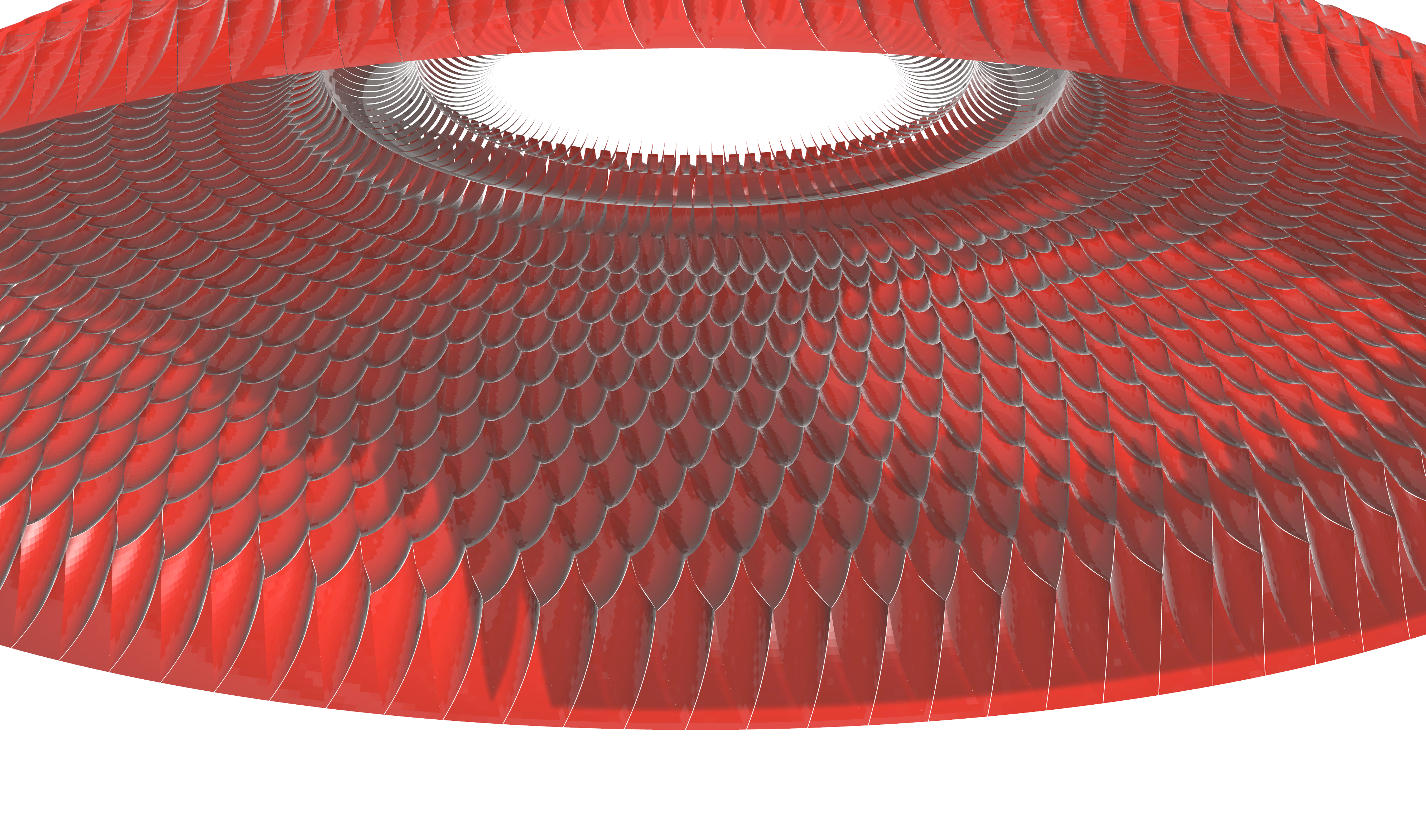

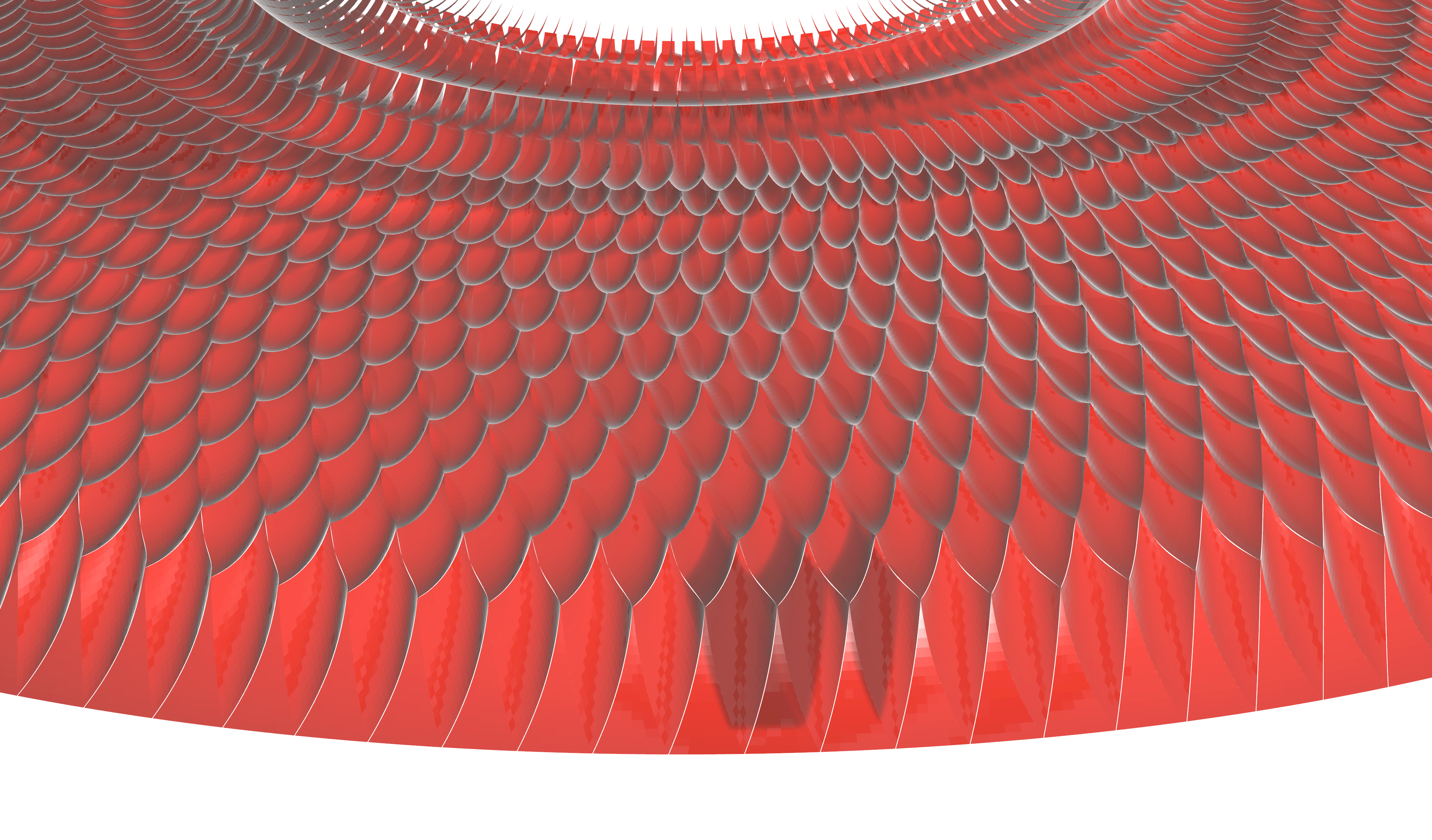

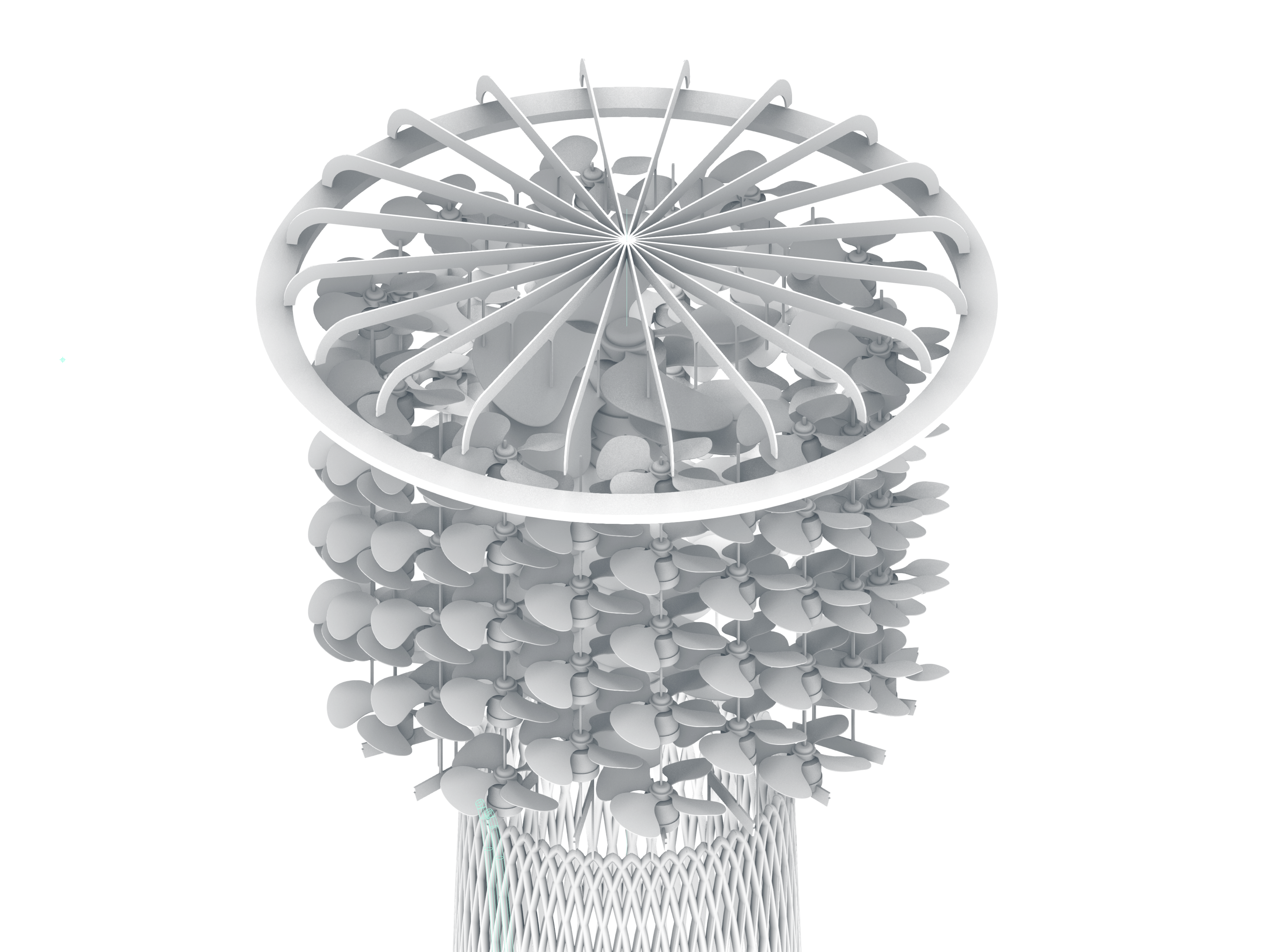

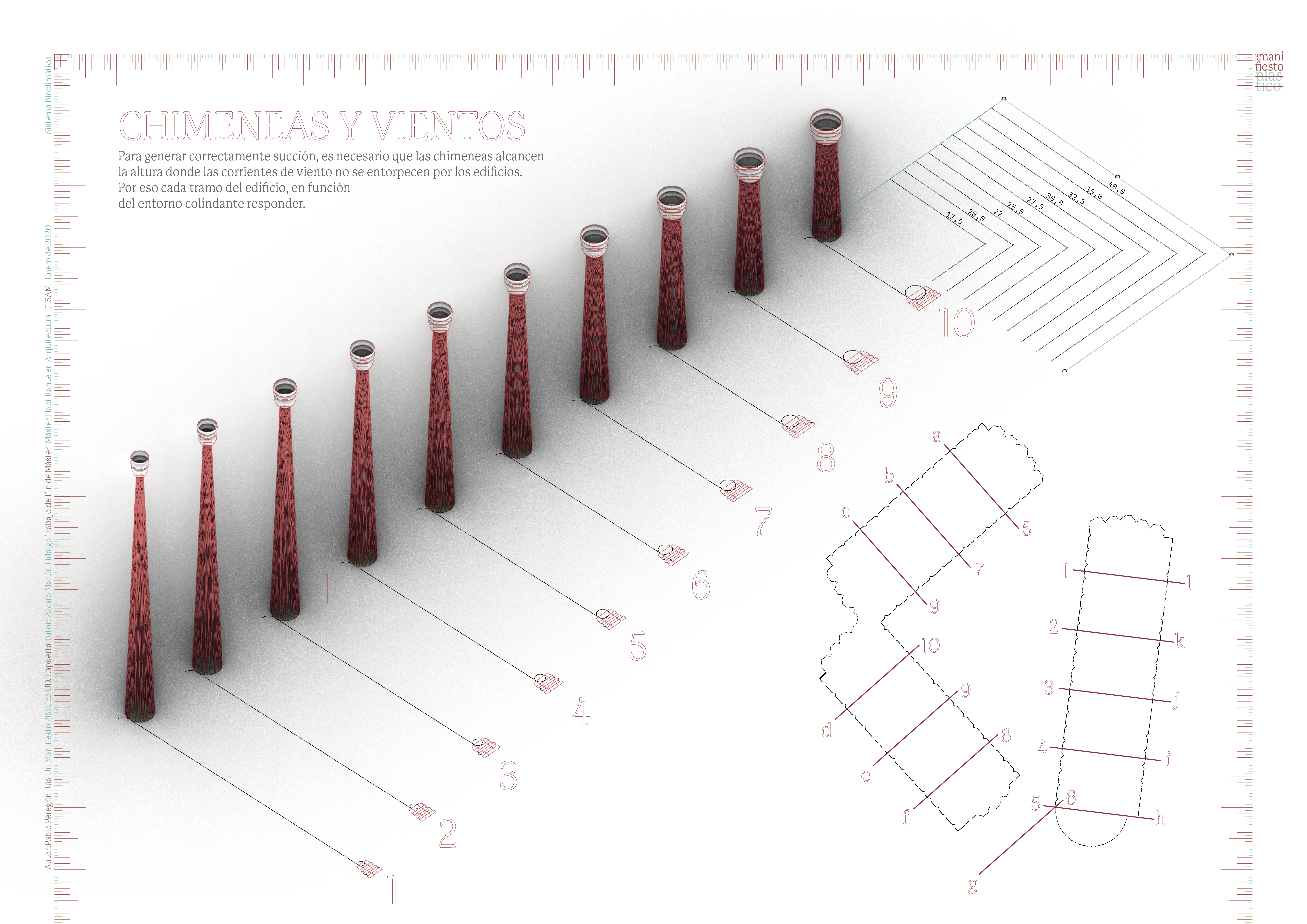

In 54 concentric brackets welded to these rings, we introduce an extractor hood with a structure of aluminium tubes arranged like the ribs of the NERVI domes, which is transformed in its lantern into a chimney with a variable shaft, made up of

a surface ruled by the same aluminium tubes.

From each node an infrastructure will be deployed based on hoses made from the biopolymers manufactured and which we will use to pump water from the river, heat it by exposure to the sun until it boils and expel it to the turbines at the crown of the chimneys.

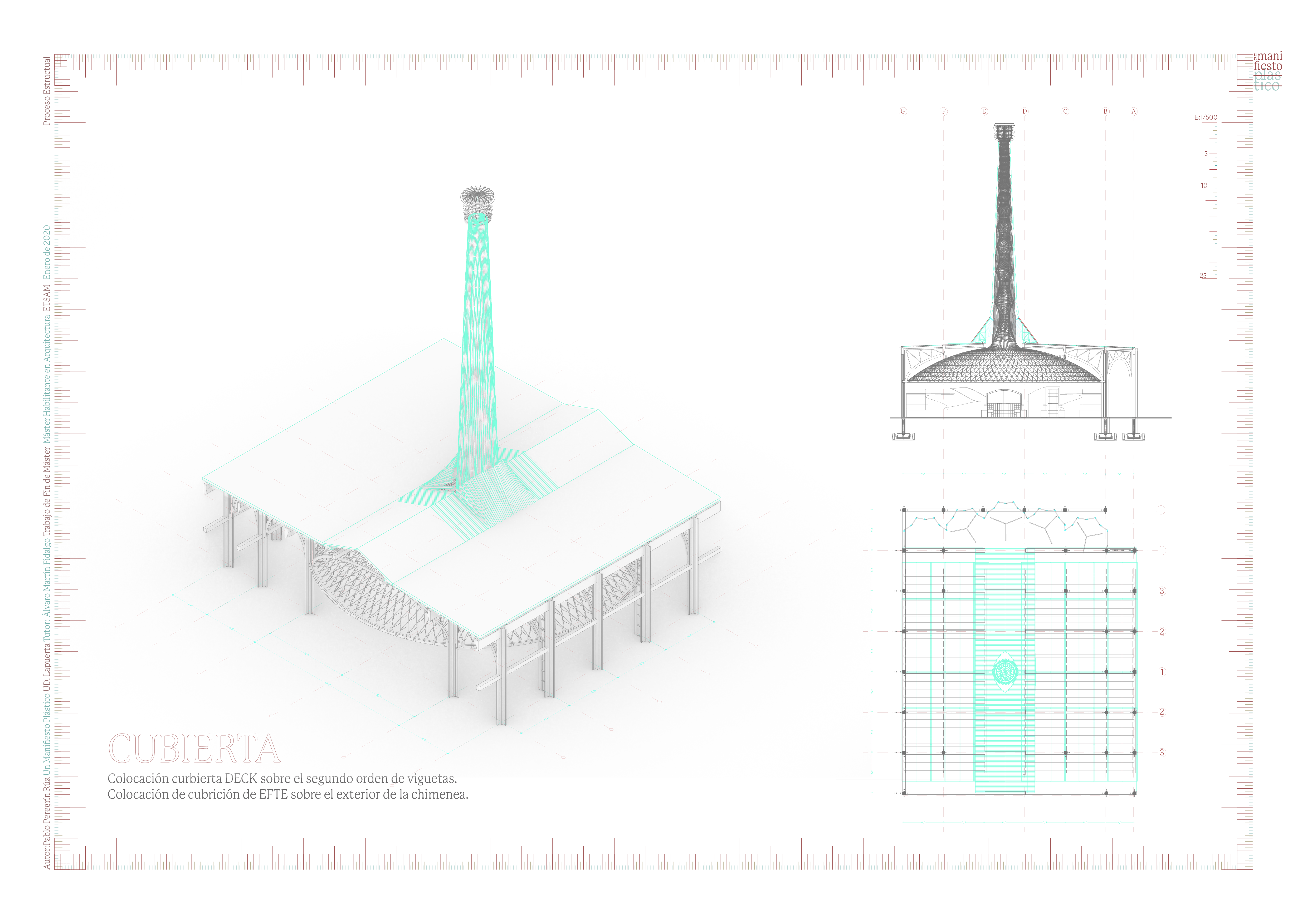

The pipes of the dome will be joined by means of two clamps, and threaded spheres will be used in the chimney, which will also support the EFTE enclosure that will make up the envelope of this chimney.

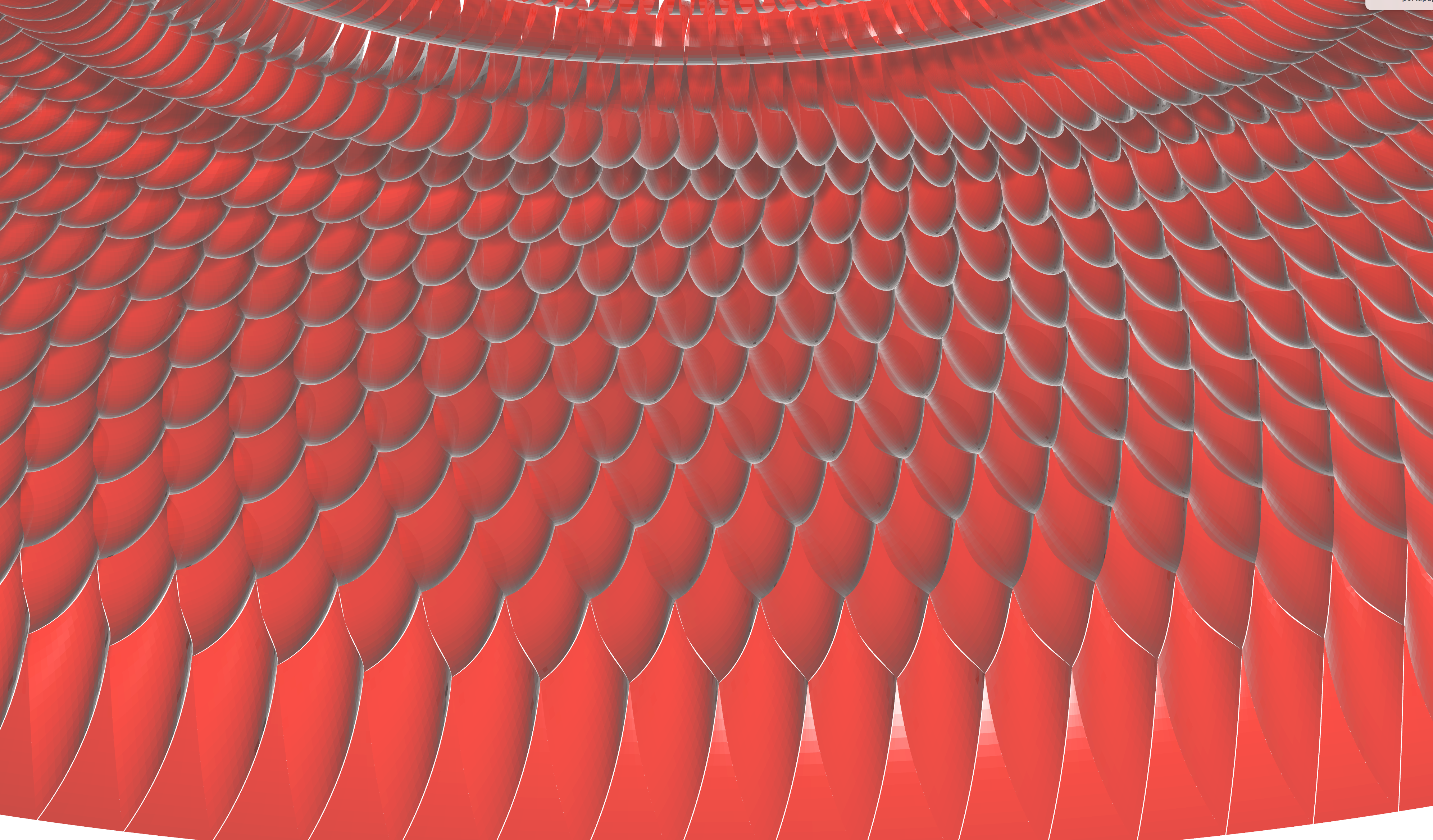

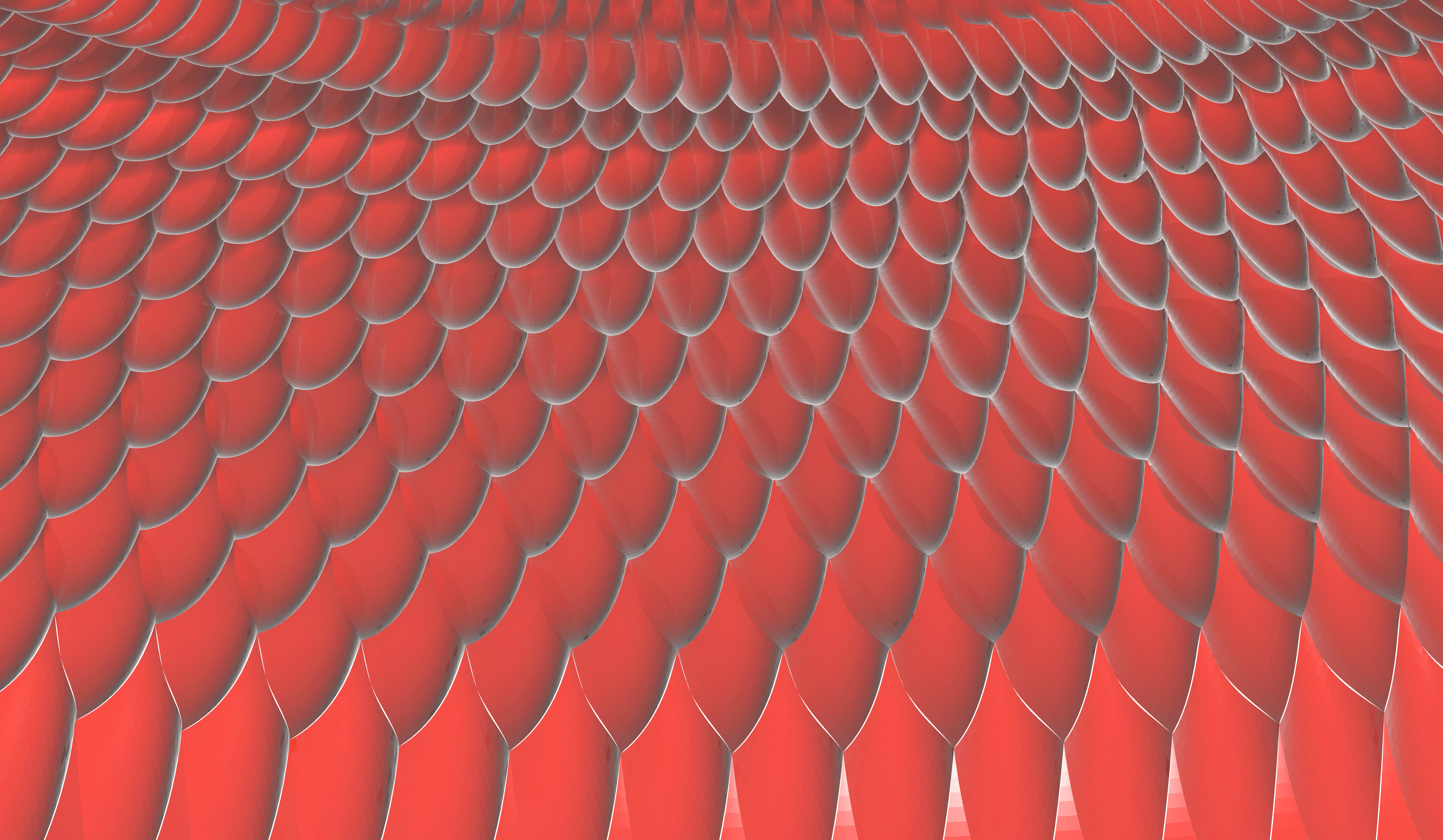

Soft membranes of the same biopolymer will be suspended between the hoses.

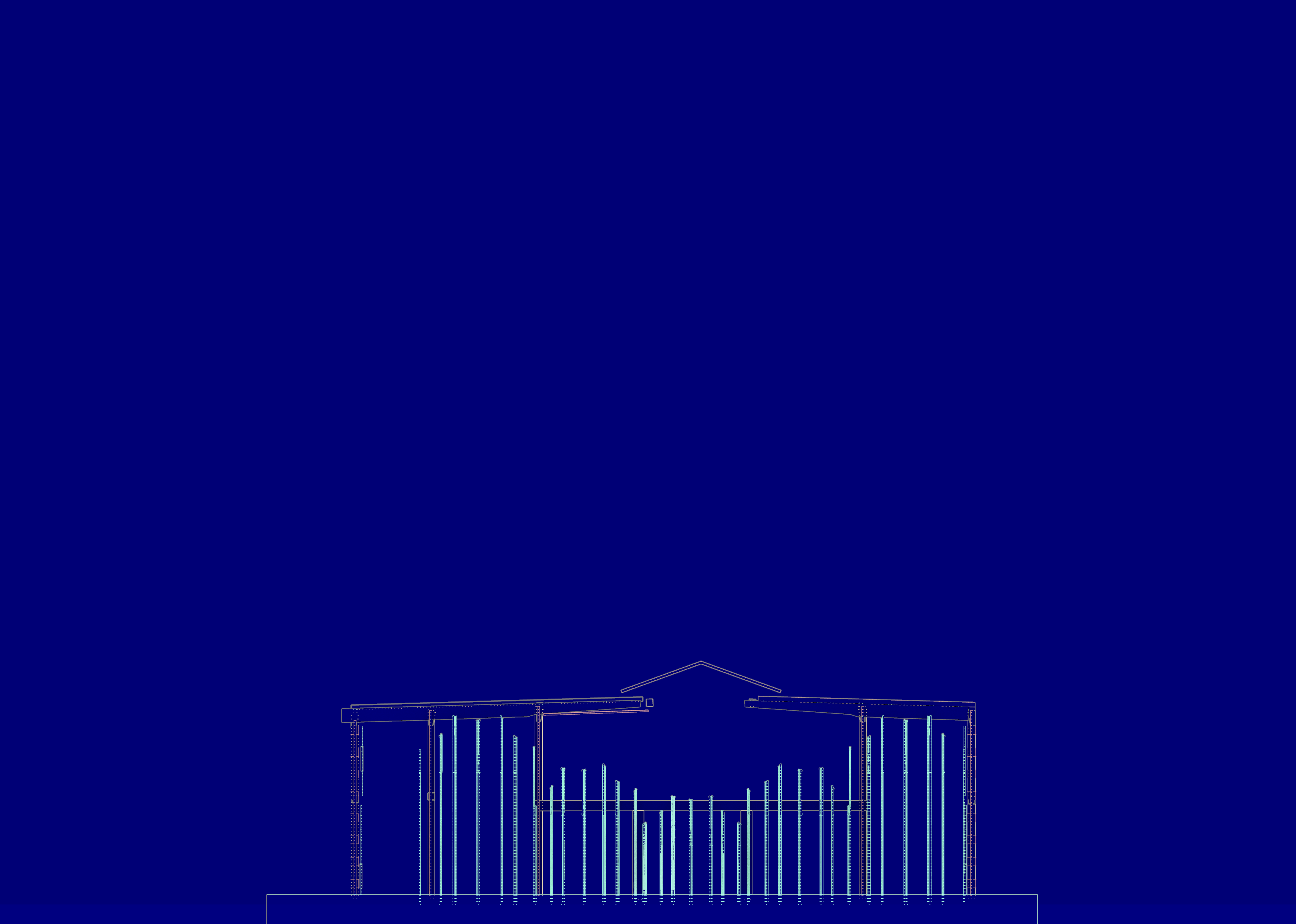

Each building produces a different type of biopolymer, due to the processing of its waste. Therefore, their interiors will have different materiality depending on the origin of the food, animals from the sea, animals from the land and vegetables.

These membranes increase, on the one hand, the acoustic absorption surface to reduce the noise inside the market, and on the other hand, they increase the light reflectance, to intensify the natural lighting inside the building.

Each module will have a chimney and different crowns, adapting to the air currents generated by the height of the adjoining buildings, the slaughterhouse, the square, the river and the m-30.

On the one hand, to guarantee the extraction of odours from inside the market, and on the other, to house a bio-climatic system to guarantee the comfort of the building and generate energy.

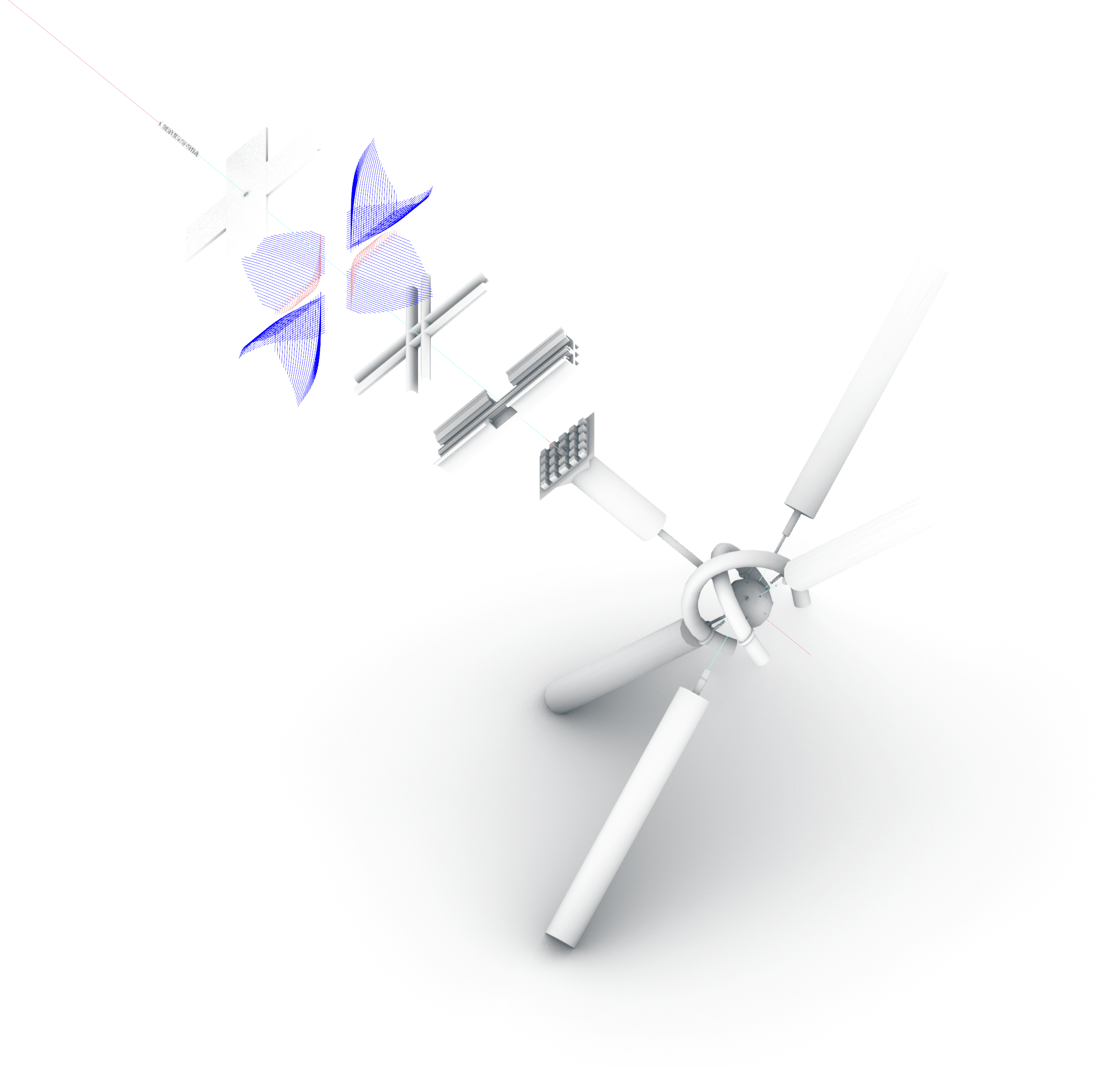

Bioclimatic System

This crown is made up of a network of turbines that convert mechanical energy into electrical energy, turbines that are activated by the pressure of water vapour, a water vapour that comes from a stream of water evaporated by exposure to the sun, thanks to an efte envelope that allows radiation to pass through, but not the cold, a stream of water that has run through the entire network of hoses from its base, filled in by a large pipe filled by pumping water from the Manzanares river.

These pumps will be powered by energy produced on the semi-flat roof, which will have a network of solar collectors.

Summer dynamics.

During the summer, a Canadian shaft cools the hot air from the street due to the thermal inertia of the ground and brings it into the building. The kinetic suction generated by the geometry of the chimney will absorb the hot air, the fumes from the stalls and the bad smells, activating the air circulation of the building.

In addition, the thermal inertia transmitted by the water to the hoses will regulate the interior temperature.

Winter dynamics.

During the winter, the Canadian well and the water pipe will reverse the hot/cold system, and in addition, the thermal inertia of the photovoltaic roof will provide heat and prevent losses.

©2024 Peregrin Rua All Rights Reserved

peregrinrua@gmail.com +34 644412104